24

SERVICING & REPLACING PARTS – Page 24

4)

INSULATION (Continued)

f)

Carefully replace burner.

g)

Refit hot surface igniter WARNING this component is

fragile and requires careful handling.

h)

Replacement is the reverse of removal.

5)

BURNER

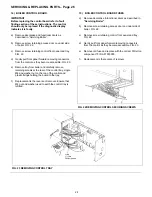

7)

FLUE HOOD/COMBUSTION CHAMBER SEALS.

a)

Remove combustion chamber/fluehood as described

in “Servicing Boiler” See Fig.17.

b)

Remove old seal.

c)

Clean groove Lising a soft brush or dry lint free cloth.

d)

Ensure new seal is correct (flue hood and combustion

chamber require different seals).

e)

Lay seal over groove and gently push into the groove

until fully home.

See

servicing instructions

for reassembly of boiler.

8)

INJECTOR

a)

Remove decorative and functional doors as described

in

“Servicing Boiler”.

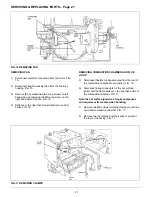

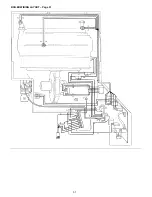

FIG. 20 REMOVAL OF BURNER

a)

Remove combustion chamber as described in

“Servicing Boiler”.

b)

Remove 8 M5 screws retaining burner to the

combustion chamber. FIG. 20.

c)

Remove burner from the combustion chamber.

d)

Ensure the burner is fitted with the gasket supplied

with it.

e)

Taking care not to damage the burner surface, install

new burner into combustion and secure with 8

screws.

f)

Reassemble as described in section

“Servicing

Boiler”.

6)

SYPHON

a)

Remove decorative and functional doors as described

in

‘Servicing Boiler”.

b)

Remove fan see

“Servicing Boiler”

.

c)

Disconnect flexible condensate pipe from the rear of

the combustion chamber/sump casting. FIG. 16.

d)

Disconnect syphon from its wastepipe. See FIG. 11.

e)

Undo nut securing Syphon to the bottom of the boiler

casing.

f)

Relacement of the Syphon is the reverse of removal.

See servicing instructions for reassembly of boiler.

b)

Remove fan see

“Servicing Boiler”

.

c)

Remove injector by unscrewing from gas supply pipe.

d)

Replacement is the reverse of removal.

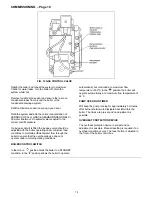

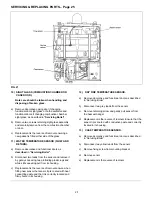

9)

GAS VALVE ASSEMBLY

Warning always ensure before filling that the

correct assembly is being used, they are provided

preset for different boiler outputs.

a)

Remove decorative and functional doors as described

in

“Servicing Boiler”.

b)

Remove fan as described in

“Servicing Boiler”.

c)

Disconnect electrical supply lead at the gas valve by

removing the two retaining screws and unplug.

d)

Remove 4 M5 screws securing gas control valve to

boiler service cock.

e)

Remove 6 MS screws retaining gas assembly

mounting plate 4 MS on the left underside of the plate

and two within the casing. Remove MS screw

attaching the valve to its mounting bracket.

f)

Slide gas assembly forward and remove from boiler.

g)

Remove flexible tube from assembly and fit to new

gas assembly.

h)

Replacement is the reverse of removal ensuring a

new gasket is fitted between casing and mounting

plate and the “0” ring seal is correctly positioned

between the gas control valve and the boiler service

cock.

Summary of Contents for envoy 30

Page 4: ...4 TECHNICAL DATA PAGE 4 FIG 2 GENERAL ARRANGEMENT ...

Page 28: ...28 FAULT FINDING CHART 1 Page 28 ...

Page 29: ...29 FAULT FINDING CHART 2 Page 29 ...

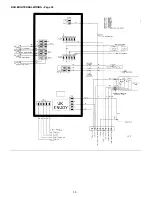

Page 30: ...30 BOILER INTERNAL WIRING Page 30 ...

Page 31: ...31 BOILER WIRING LAYOUT Page 31 ...

Page 36: ...36 Back Page ...