6

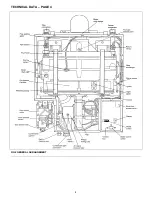

INSTALLATION REQUIREMENTS – Page 6

Where a room-sealed appliance is installed in a room

TABLE 1

containing a bath or shower, any electrical switch or

AIR VENT AREAS

appliance control, utilising mains electricity should be

in

2

cm

2

so situated that it cannot be touched by a person

30

16

103

using the bath or shower.

40

21

135

50

26

170

Where the installation of the boiler will be in an

60

32

206

unusual location, special procedures may be

80

43

277

necessary and BS.6798 gives detailed guidance

on this aspect.

It should be noted that due to the high efficiency of this

boiler a white plume of condensate will be emitted from

the flue terminal therefore care should be taken when

selecting the terminal position.

Ensure that the gas supply pipe and meter are large

enough for the appliance and any others that may be

run off the same meter. Reference should be made to

BS.6891.

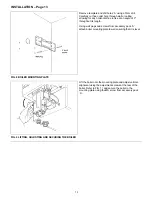

BOILER MOUNTING SURFACE

The boiler must be mounted on a flat wall, which may

be of combustible material and must be sufficiently

robust to take the weight of the boiler. The requirements

of the local authorities and the Building Regulations

must be adhered to.

IMPORTANT NOTICE:–TIMBER FRAMED HOUSES

If the appliance is to be fitted in a timber framed

building, it should be fitted in accordance with British

Gas Publication ‘Operational Procedures for Customer

Service’ Part 19. If in any doubt, advice should be

sought from the local region of British Gas.

CLEARANCES AROUND THE BOILER

The following minimum clearances must be maintained

after installation, for correct operation and servicing of

the boiler:

610mm (2ft)

at the front of the boiler

5mm (0.2 in)

each side of the boiler

140mm (5.5 in)

at the top (measured from the top

of the boiler case)

100mm (4 in)

at the bottom of the boiler

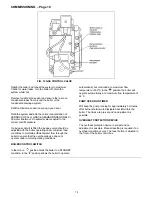

VENTILATION

If the boiler is to be installed in a confined space such

as a cupboard, the space will need ventilating.

Openings must be provided at the top and bottom of the

cupboard each of which should have a free area as

shown in TABLE 1. Further details for installation of a

boiler within a compartment are given in BS.6798.

If the openings draw air from outside the building the free

areas may be halved. Refer to BS.5440 Part 2 for further

guidance.

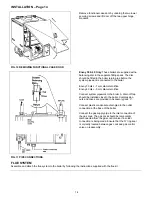

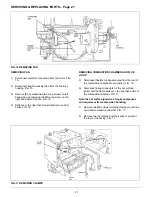

FLUE TERMINAL AND DUCTING (Fig. 3a, b & c)

The standard

horizontal

flue system (Potterton Part No.

236346) is suitable for installations up to 1030mm,

measured from the centre line of the boiler outlet to the

outside face of the wall.

One metre flue extension kits

(Part No. 430085)

are available to extend horizontal flues to a maximum

length of 2920mm. The siting positions for horizontal flue

terminals are shown in Figs. 3a, b & c.

A concentric vertical flue

system is available (Part No.

236348) which when used in conjunction with

one metre

flue extension kits (Part No.

430085) is suitable for flue

heights up to 3 metres to terminate through a roof.

The siting of the flue terminal through a roof is shown in

Fig. 3c.

Only the above flue systems should be used with Envoy

boilers.

As with all condensing boilers, the flue will produce a

plume of visible condensation for much of the time that

the boiler is running.

Care must therefore be taken in the siting of the terminal

so as not to be a nuisance to adjacent property.

In particular, prolonged wetting of a facing wall should be

avoided, if necessary by use of an appropriate deflector.

If a horizontal flue is sited less than 2m above a balcony,

above ground, or above a flat roof to which people have

access, a suitable terminal guard must be fitted. This

serves two purposes, to protect the terminal against

damage or interference and to protect passers-by. A

terminal guard is available (Part No. 236591).

Summary of Contents for envoy 30

Page 4: ...4 TECHNICAL DATA PAGE 4 FIG 2 GENERAL ARRANGEMENT ...

Page 28: ...28 FAULT FINDING CHART 1 Page 28 ...

Page 29: ...29 FAULT FINDING CHART 2 Page 29 ...

Page 30: ...30 BOILER INTERNAL WIRING Page 30 ...

Page 31: ...31 BOILER WIRING LAYOUT Page 31 ...

Page 36: ...36 Back Page ...