23

SERVICING & REPLACING PARTS – Page 23

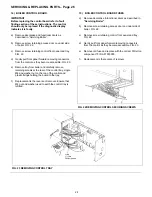

7)

Replacement of components is the reverse of

removal.

Note

great care should be taken not to damage the flue

hood and combustion chamber seals during replacement

of these assemblies.

8)

When refitting straps ensure that they are located

correctly in the guides on both the flue hood and

combustion chamber.

9)

Ensure that screws are fully tightened and clamps fix

the combustion chamber and flue hood securely.

10)

Ensure connection from sump to syphon is made

before refitting fan.

11)

Ensure that the gaitor between the flue hood and

elbow is correctly positioned untwisted and forms a

good seal to both components.

12)

Relight the boiler as described by following the

lighting procedure in the commissioning section of

these instructions.

REPLACEMENT OF PARTS

Before replacing any component carry out pre-check

detailed at the beginning of the Service section and

then refer to fault finding section of these

instructions.

WARNING

Before the start of any servicing or replacement of parts

ensure that you have:

a)

Switched off at the external electrical supply by

removing the plug from the wall socket or by

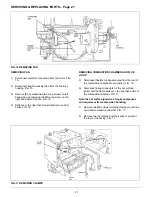

3)

FLAME SENSOR

a)

Remove combustion chamber as described in

“Servicing Boiler”.

b)

Remove screw retaining sensor and withdraw from

the combustion chamber. See FIG. 19.

c)

Replacement of the sensor is the reverse of removal,

ensure new gasket is always fitted.

switching off the appliance at the external isolating

switch.

b)

Isolated the gas supply at the boiler service cock.

If the combustion chamber has been removed follow

procedure in Service section “Re-assembly of boiler”

1)

FAN

a)

Follow procedure in “Preparation for servicing” at the

beginning of the servicing section.

b)

Replacement of fan is the reverse of removal.

2)

HOT SURFACE IGNITER

WARNING

this component is fragile and requires

careful handling.

a)

Remove combustion chamber as described in

“Servicing Boiler”.

b)

The igniter assembly is retained by two MS pozi drive

screws. Remove screws and carefully remove old

igniter, if the igniter has become damaged, invert the

combustion chamber and shake gently to allow

damaged segments to be removed from the chamber.

See FIG. 19.

c)

Replacement of the igniter is the reverse of removal

ensure that a new sealing gasket is always fitted and

that a good seal is made between the igniter and

combustion chamber.

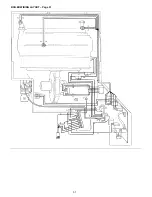

FIG. 19 HOT SURFACE IGNITER & FLAME SENSOR

4)

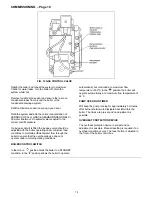

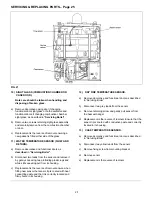

INSULATION

Note all four insulation pads must be replaced.

a)

Remove combustion chamber as described in

“Servicing Boiler”.

See FIG. 17.

b)

Remove burner FIG. 20 hot surface igniter and flame

sensor. FIG. 19.

c)

Remove old insulation.

d)

Replace front pad first ensuring that bevelled edge is

uppermost and fits into the chamber correctly.

e)

Fit rear pad and use end insulation to retain rear pad.

Summary of Contents for envoy 30

Page 4: ...4 TECHNICAL DATA PAGE 4 FIG 2 GENERAL ARRANGEMENT ...

Page 28: ...28 FAULT FINDING CHART 1 Page 28 ...

Page 29: ...29 FAULT FINDING CHART 2 Page 29 ...

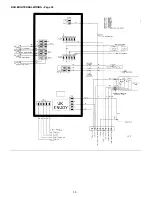

Page 30: ...30 BOILER INTERNAL WIRING Page 30 ...

Page 31: ...31 BOILER WIRING LAYOUT Page 31 ...

Page 36: ...36 Back Page ...