116

I-Class

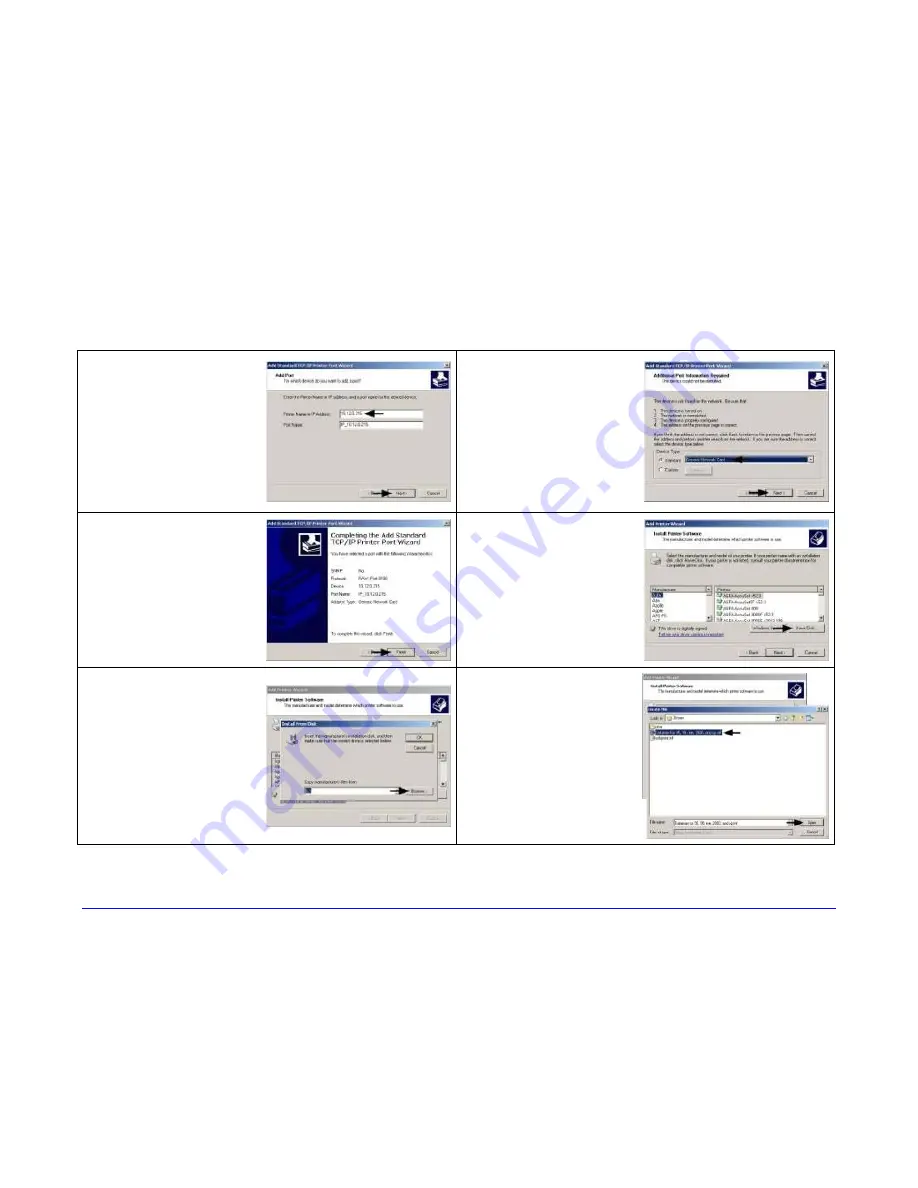

Windows XP Driver and Port Installation (continued)

5

In the Printer Name

or IP Address field

enter the IP

address of your

printer. The Port

Name field does not

need to be

changed. When

finished click

“Next”.

6

Ensure Standard is

selected and then

click Next.

7

Confirm your

settings and then

click Finish.

8

Click on Have Disk.

9

Insert the

Accessories CD-

ROM and click

Browse.

10

Browse to the

“\DRIVERS\Seagull”

folder on the CD-

ROM, ensure the

file “for 95, 98, ME,

2000, and xp.inf” is

selected and click

OK.

Summary of Contents for I4208

Page 2: ...Operator s Manual ...

Page 3: ......

Page 7: ......

Page 17: ...6 I Class ...

Page 29: ...18 I Class ...

Page 69: ...58 I Class ...

Page 95: ...84 I Class ...

Page 115: ...104 I Class ...

Page 119: ...108 I Class ...

Page 133: ......