6.

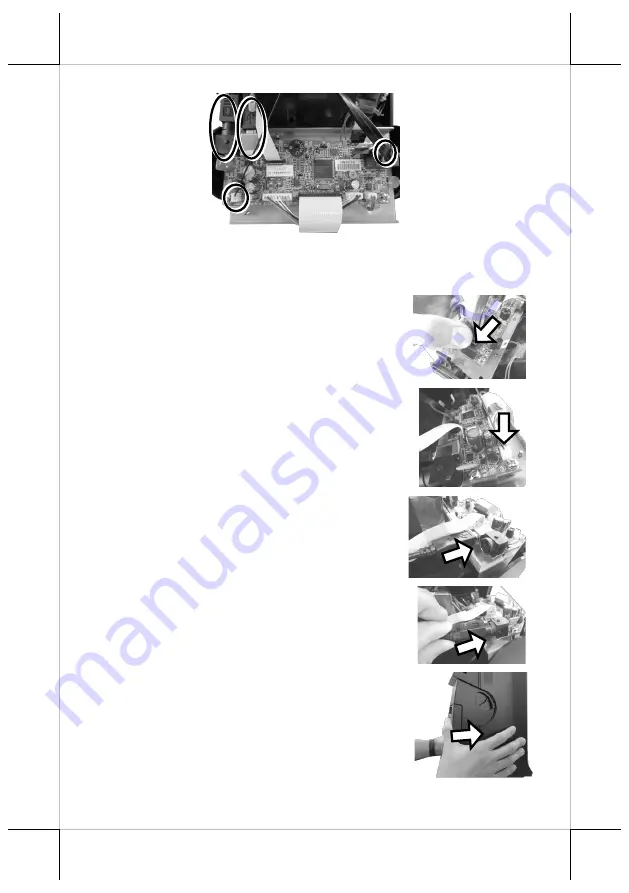

Disconnect all the cables indicated in the figure.

7.

Take the new printer module which you wish to replace with, and then

connect the cables to the printer control board as indicated in the

following figures.

7.1

Connect the CR cable to CR port on the

control board.

7.2

Insert the cable to the port for printer

signal on the control board.

7.3

Attach the USB cable to Type-B USB

port on the control board.

7.4

Plug the cable to DC-IN power jack on

the control board.

8.

Carefully support the printer module

with both of your hands and then push it

back into the rear case of HS-series

terminals.

10