Spraying Tips

1. The stroke is made with a free arm motion, keeping the gun at a right angle

to the surface at all points of the stroke. Arching the stroke will result in

uneven application and excessive over spray at each end of the stroke.

2. Depress trigger just before reaching the edge of the surface to be sprayed.

Hold the trigger fully depressed and move the gun in one continuous

motion. Release the trigger when the other edge of the surface is reached,

shutting off the fluid flow, but continue motion a few inches until it is

reversed for the return stroke. When the edge of the surface is reached on

the return stroke, depress the trigger fully again and continue across the

surface.

3. Lap each stroke 50% over the preceding one. Less than 50% will cause

streaks on the finish surface.

NEVER point spray gun at self or any other person.

Accidental discharge of material may result in serious injury.

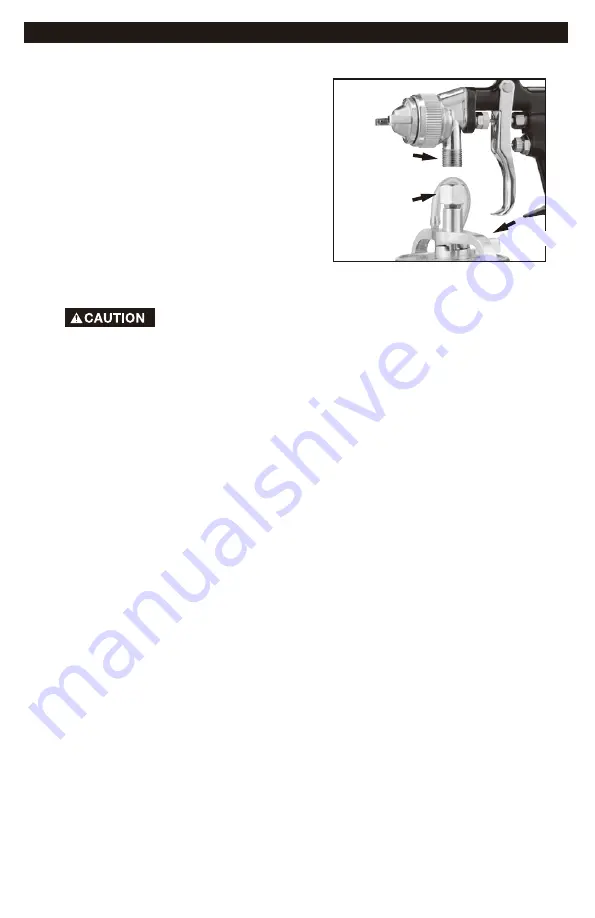

NOTE: When replacing lid assembly to gun assembly hand tighten nut (b)

and tighten securely.

If the material to be sprayed is too heavy for siphon feed or fast application

is desired, convert to the pressure feed.

1.

Remove the

material cup (e)

lever (f) to the right, rotate lid, and

remove

material cup (e).

2.

Loosen nut (b). After the nut

is loosened hand turn until lid

assembly can be removed from gun.

3.

The gun is now ready to be

connected to any pressure feed tank

with a standard 3/8" straight pipe

female connection. See manufacturer’s

manual for correct procedure.

4.

To operate see steps 5-7 in the "Operation" section to continue.

CONVERT TO REMOTE PRESSURE FEED

3/8 NPS

Fluid

Connention

b Nut

a Lever