Operating manual liquid ring vacuum pumps TRVK - TRSK

17

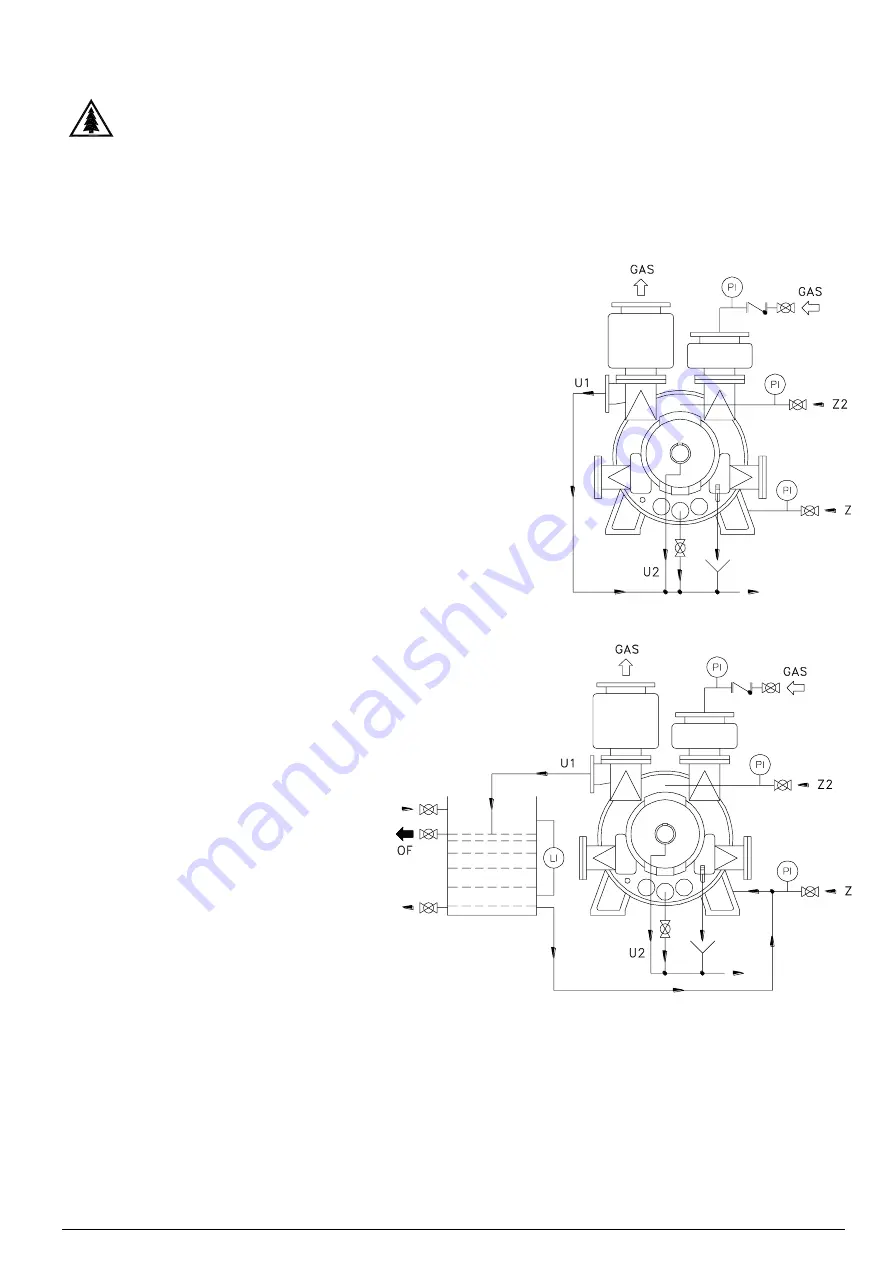

9.3 - INSTALLATION SCHEMATICS FOR LIQUID RING VACUUM PUMPS

The working principle of the vacuum pump requires a continuous flow of fresh and clean liquid that enters the pump at

the service liquid connection identified by the letter “Z” (see following chapter). The liquid is discharged together with the

handled gas through the pump discharge flange.

Take care of their disposal according to the laws into force and to a safe local environment management.

The quantity of said liquid will vary with pump size and degree of working vacuum (see performance curves).

The service liquid absorbs the compression heat generated by the pump compression therefore its temperature will rise

by some 4°C to 8°C according to working point.

There are three basic installation schematics listed below that may be considered, depending upon the quantity of service

liquid that is desired and possible to be recycled.

9.3.1 - Service liquid: Once-through system (no recovery)

All the service liquid is supplied from an external source.

The liquid is separated from the gas in the manifold separator and drains

directly through the discharge connection located at the bottom of the

manifold separator itself.

This is the most common installation scheme and can be applied when it

is available an abundant constant flow of fresh liquid and/or when the

liquid contamination problem never exist, liquid that can be harmful for the

surrounding environment: therefore provide a proper disposal according

to laws into force.

The service liquid should be supplied at the pump connection with a

pressure of 0.2 to 0.4 bar maximum to avoid flooding the pump with too

much liquid.

If this is not possible it is recommended to install a reservoir fitted with a

float valve, this tank is supplied with the liquid that is then pulled by the

pump as required by the operating conditions.

The liquid level in the reservoir should be approximately at the pump shaft

centreline.

Schematic fig. 18 illustrates the once-through system.

9.3.2 - Service liquid: Partial recovery system

This type of installation is used where it is

desired to minimise the use of fresh service

liquid.

The service liquid enters and leaves (take care

of its eventual disposal according to the laws

into force and to a safe local environment

management) the pump same as the once

through system, however part of the liquid is

recycled from the discharge separator and the

balance is continuously supplied from an

external source. The excessive liquid is drained

through the separator overflow connection.

The temperature of the mixed liquid supplied to

the pump will be higher than the temperature of

the make-up liquid. Its final temperature will

depend upon the amount of the recycled liquid.

It is important to remember that with higher

service

liquid

temperature

the

pump

performance will decrease (see chapter 17)

with the possibility of operating the pump in the

cavitation area.

When the separator tank is installed along side

of the pump (our type HSP), its liquid level

should not be above the pump shaft centreline.

Schematic fig. 19 illustrates the system with partial recovery of the service liquid.

C

= Cooling circuit

OF

= Overflow

U1

= Service liquid discharge

U2

= Packing flushing liquid discharge

Z

= Service liquid inlet

Z2

= Inlet flushing liquid for packing

Fig. 18

Fig. 19

Summary of Contents for TRSK 2002/1

Page 1: ... NA4 IS VUOC IN00 Rev 3 8_11 2020 OPERATING MANUAL LIQUID RING VACUUM PUMPS TRVK TRSK ...

Page 10: ...Operating manual liquid ring vacuum pumps TRVK TRSK 10 90 OK NO Fig 2 Fig 4 Fig 1 Fig 3 ...

Page 28: ...Operating manual liquid ring vacuum pumps TRVK TRSK 28 blank page ...

Page 29: ...Operating manual liquid ring vacuum pumps TRVK TRSK 29 blank page ...

Page 30: ...Operating manual liquid ring vacuum pumps TRVK TRSK 30 blank page ...