of the included 0.1″ header strip and solder it into the smaller through-holes that border the

six large motor and motor power pads. Note, however, that each header pin pair is only

rated for a combined 6 A, so for higher-power applications, the terminal blocks should be

used or thick wires with

high-current connectors

[https://www.pololu.com/product/925]

should

be soldered directly to the board.

3.

Enable Jumper:

You can optionally solder a wire or a 2×1 piece of the included 0.1″ male

header strip to the two pins highlighted in orange in the above diagram to create a board

enable jumper. The left pin is D2, and the right pin is VDD. D2 is internally pulled low, which

tri-state disables the motor driver outputs and allows any connected motor to coast. In order

to enable the board, this pin must be driven high, either through a connection to an I/O line

or by connecting it to the neighboring VDD pin.

With the exception of the pins labeled “D2 1=2” and “SF 1=2”, all of the through-holes not highlighted

in the above diagram are only relevant when using this driver as an Arduino shield. The “D2 1=2” and

“SF 1=2” pins are explained in the “Pinout” portion of

Section 4.b

, but they will not be needed in typical

applications and can generally be ignored.

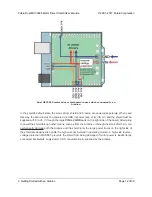

4.b. Board Connections

Using the dual MC33926 motor driver shield with a microcontroller (gray connections are

optional).

The above diagram shows the minimum connections typically required to interface this motor driver

with a microcontroller. Note that D2 is internally pulled low, which disables the motor outputs; it must

either be connected to an I/O line (for dynamic control) or soldered to the neighboring VDD pin to

Pololu Dual MC33926 Motor Driver Shield User’s Guide

© 2001–2017 Pololu Corporation

4. Using as a General-Purpose Motor Driver

Page 20 of 30