POK SAS - 18 Cours Antoine Lavoisier - 10400 Nogent-sur-Seine - FRANCE

Phone: +33 (0)3 37 49 53 000 - Email: [email protected] - Web: www.pok-fire.com

MIXY EDUCTOR

-

Eductor 400 lpm, in aluminium, male inlet and outlet couplings 2" BSP

13

MOP_PRO_02341_EN_A 08/07/2021 - Cop

yright© POK S

A

S - Illustr

ations are only informativ

e

Use

Instructions for use

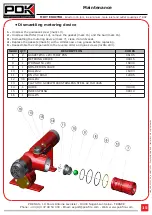

Maintenance

• Causes of malfunctions - solutions

1 -

Impureties or particles in the entrance cone could prevent the eductor from functioning properly. These

particles can been carried by a dirty suction rod or water. Follow the steps detailled "disassembly exit/

entrance cone” (page 14) to clean the suction chamber

2 -

A waterhammer may have moved the membrane of the control valve. To remove the membrane and

put back in its place, follow the steps detailled “disassembly the control valve” (page 15). Open and close

smoothly valves avoiding this.

3 -

The direction of assembly must always be respected. Be sure the arrow on the body of the eductor show

the flow direction (page 11).

4 -

The functioning of the eductor may be affected if the metering device cannot be turns or turns roughly

Follow the steps “disassembly metering device” (page 15) to set or replace the metering device.

5 -

The body of the eductor protects the entrance and the exit cone from bump and a filter from particles.

However, particles carried by water may damage these parts over time. Then, replace these by paying

attention to the flow rate of the spare pieces. Follow the steps “dismantling entrance/exit cone” (page 14).

6 -

Due to a bump or a crushing, the body of the eductor may been distorted or internal components broken.

Replace the eductor by a new one. If it seems fixable, you can request a price quotation.

7 -

The eductors are designed to work with foam equipment with a similar flow rate. The European standard

requires a pressure of 6.5 bar at the outlet for a pressure of 5 bar at the foam branchpipe inlet.

If the pressure loss is higher than 1.5 bar (hose too long or branchpipe too high

comparative to the eductor), the device will no longer working and can not suck up

the emulsifier.

As a reminder, each elevation meter between the eductor and the branchpipe raise the pressure loss of 0.1

bar. The eductor is designed to suck up to 1.5 meter above the emulsifier. Beyond, the device can not suck

up the emulsifier, except for specific design.

Depending on the bend radius, a 90° turn generate a significant pressure loss, any break or fold must be

avoided in the hoses.

8 -

According to the mode and frequency of use, leakage may appear at the metering device due to the wear

of gaskets. If this occurs, follow the steps “dismantling metering device” (page 15).

It is important to check, after each use, that no part is missing or damaged. Where necessary, please

replace it as soon as possible.