5

A. Install the dryer INDOORS in an area where the

ambient temperature will be above 55°F (13°C) and

below 100°F (38°C). Temperatures below 55°F

(13°C) and above 100°F (38°C) may cause erratic

operation of the air dryer. Air-cooled dryers must be

installed INDOORS in a location with proper

ventilation which will maintain ambient temperatures

as specified above.

B. Position the dryer to permit free circulation of cooling

air through the condenser. Keep two feet minimum

clearance space around the dryer, and also on the

top for servicing. Lack of ventilation can build up the

room temperature by recirculating the same cooling

air through the condenser over and over again. This

will eventually shut down the refrigerant compressor

on high head pressure and/or on internal overload.

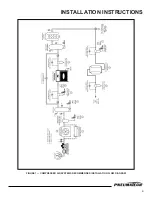

C. Connect the compressed air to the dryer inlet.

Connect the plant compressed air line to the dryer

outlet. A three-valve bypass around the dryer is

recommended for dryer service. See Figure 1. A

coalescing afterfilter is recommended for oil-flooded

air compressor systems.

D. Make sure when piping is in place that no undue

stress is placed on dryer connections. Union joints

or flexible connections are recommended to relieve

stress. Also, properly support the pipes as needed

with hangers or brackets. Air piping must be

installed by an experienced pipefitter.

E. An aftercooler (air-cooled or water-cooled) must be

installed between the air compressor and the dryer.

Installing the dryer without the proper aftercooler will

bring high inlet temperature compressed air to the

air dryer which will cause premature failures.

Aftercoolers must be followed by a separator and an

automatic drain to remove the condensed moisture

before the compressed air reaches the air dryer.

If the condensed water is not removed at the

aftercooler/separator/drain, it will reduce the cooling

capacity of the air dryer. Aftercoolers will condense

approximately 2-1/2 to 3 times more water than that

of the air dryer.

F. For models AD-750 through AD-3200, electronic

timer operated drains are standard. All dryers

include a particle strainer upstream from the drain

valve. To clean, close the shut-off valve and

depressurize the drain line.

All drain outlets may be combined for condensate

disposal. Dispose the condensate in compliance to

local and federal government requirements.

WARNING

Drain outlet tubing will periodically contain

pressurized air. An unsecured drain tube will whip

around potentially causing bodily injury.

CAUTION

Do not combine any two or more drain inlet lines

through one single automatic drain valve. This will

reduce or eliminate the proper drainage.

G. For water-cooled air dryers, connect cooling water

lines to the water-cooled condenser from the water

supply. Water pressure must be a minimum of 35

PSIG. Do not connect city water to a condenser

which is piped for tower water or vice versa.

Strainers are recommended at the water inlet to the

condenser. Proper chemical treatment is

recommended for cooling tower water to avoid

scaling and sludge inside the condenser.

CAUTION

Do not reduce pipe sizes connected to water and

drain lines. They should be the same or larger than

sizes supplied on the dryer to avoid excess pressure

drop.

Summary of Contents for AD Series

Page 15: ...14 FIGURE 6 FLOW DIAGRAM AD 750 to 1000 ...

Page 16: ...15 FIGURE 7 FLOW DIAGRAM AD 1200 to 2000 ...

Page 17: ...FIGURE 8 FLOW DIAGRAM AD 2500 to 4000 16 ...

Page 22: ...21 ...

Page 23: ...22 ...