8

7. The Expansion valve is factory set for the correct

superheat of 8 to 10°F (-13 to -12°C) and should not

be re-adjusted. If any malfunction is noticed on the

expansion valve, contact the factory or your

Pneumatech distributor.

8. Allow 10 to 15 minutes of cool down time before

adding the compressed air load.

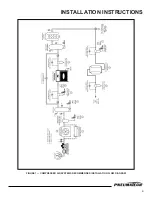

9. Keeping the dryer outlet isolation valve closed,

pressurize the dryer to the line pressure. See

Figure 1.

10. Check for any leaks in the system.

11. Slowly open the dryer outlet isolation valve to

pressurize the downstream system.

OPERATING RANGE AND

CONTROL SETTINGS

R-134a

Refrigerant Suction Pressure:

25 to 33 PSIG - Blue color range

Refrigerant Discharge Pressure:

75 to 170 PSIG Air-cooled units

115 to 135 PSIG Water-cooled units

Refrigerant Low Pressure Switch:

Cut Out 20 PSIG

Cut In 40 PSIG

Refrigerant High Pressure Switch:

250 PSIG Air-cooled units

225 PSIG Water-cooler units

Fan Control:

Cut Out 110 PSIG

Cut In 150 PSIG

R-404a

Refrigerant Suction Pressure:

69 to 76 PSIG - Orange color range

Refrigerant Discharge Pressure:

235 to 272 PSIG

Refrigerant Low Pressure Switch:

Cut Out 58 PSIG

Cut In Manual reset

Refrigerant High Pressure Switch:

425 PSIG Air-cooled units

385 PSIG Water-cooled units

Fan Control #1:

Cut Out 215 PSIG

Cut In 280 PSIG

Fan Control #2:

Cut Out 225 PSIG

Cut In 295 PSIG

Consult factory for pressure switch settings on dryers

equipped with optional Low Ambient Headmaster

control.

Summary of Contents for AD Series

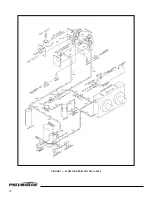

Page 15: ...14 FIGURE 6 FLOW DIAGRAM AD 750 to 1000 ...

Page 16: ...15 FIGURE 7 FLOW DIAGRAM AD 1200 to 2000 ...

Page 17: ...FIGURE 8 FLOW DIAGRAM AD 2500 to 4000 16 ...

Page 22: ...21 ...

Page 23: ...22 ...