IMPORTANT NOTES: Read First

www.playcraftsystems.com

For Customer Service Call

800.333.8519 (U.S.A.) or 541.955.9199 (International)

TRANSFER STATION WITH HALF WALLS

INSTALLATION INSTRUCTIONS

Rev F

6/3/2020

1209-HW

Page 1 of 7

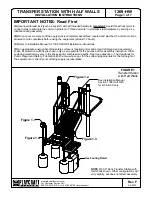

Figure 1.2

Figure 1.4

See Installation Manual

Section 1309 Half Wall

for R5 & R3.5 only.

See Footing Detail

Figure 1.1

(A)

Use liquid thread lock (such as Loctite

®

) with all threaded hardware.

Important:

Liquid thread lock (prior to

curing) helps to eliminate the common problem of "thread seizure" in stainless steel hardware by serving as a

lubricant during assembly.

(B)

Do not pour concrete until the equipment is completely assembled, leveled and plumbed. Concrete must be

allowed to cure completely before using the equipment (at least 72 hours).

(C)

Refer to Installation Manual for 1309 Half Wall installation instructions.

(D)

An appropriate energy absorbing safety surface is required under and around all playground equipment.

Loose fill protective surfacing is shown only as an example for the purpose of this assembly instruction. Other

surfacing material may vary in thickness and/or compression depths. See free publication - The Handbook for

Public Playground Safety, Publication #325 at www.cpsc.gov for the surfacing appropriate for the fall height of

the equipment or consult your surfacing supply representative.

FIGURE 1

Transfer Station

with Half Walls

NOTE

: R5 36" Deck Transfer Station with

Half Walls shown. Other configurations will

vary slightly, but does not affect assembly.

Figure 1.3