39

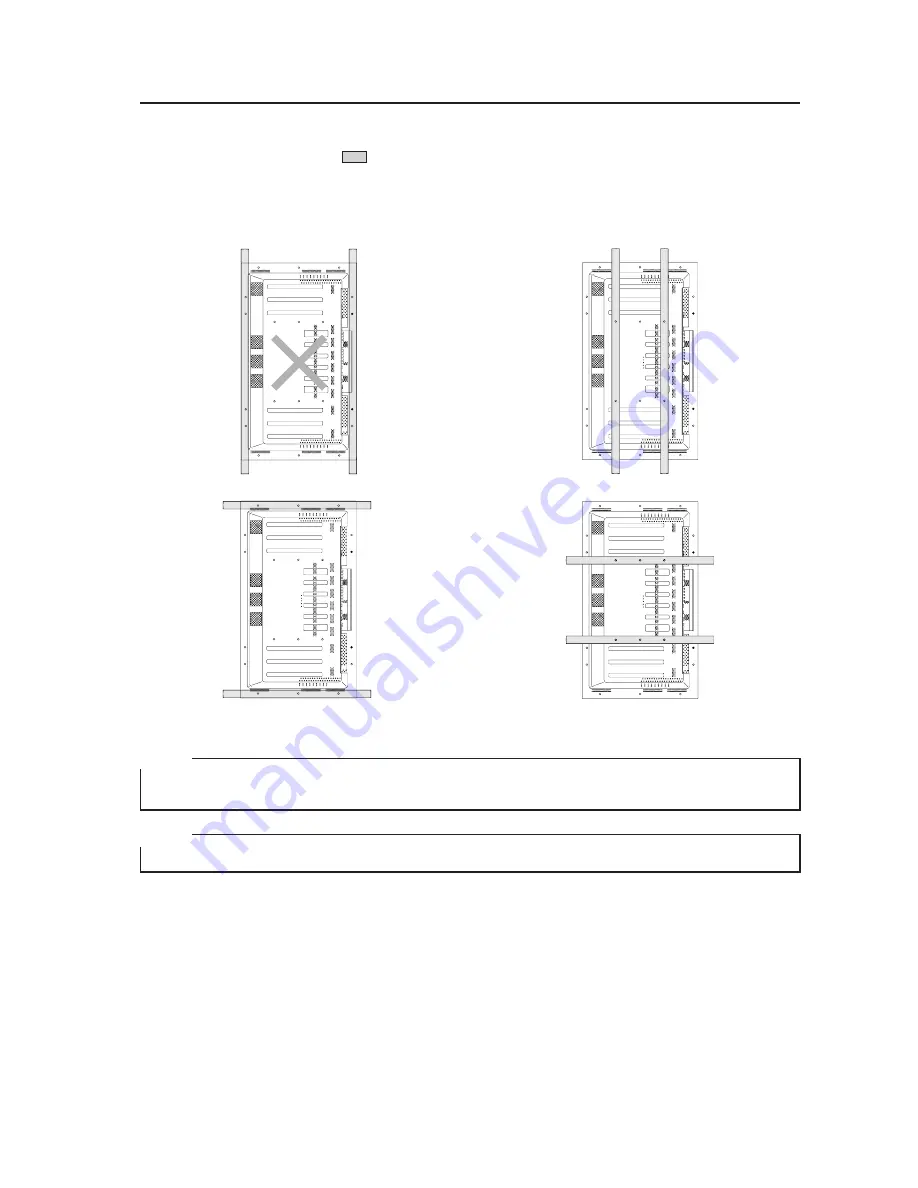

Special Installation (Hanging from the wall (lengthwise))

Methods of Securing: Basic methods of securing are shown below. Avoid blocking or covering areas aside from those

indicated by

. The method indicated by a large X-mark must not be used.

Before attaching the unit to fittings, double-check that the thickness and height of the fittings,

and the number of fixing bolts is correct.

(Also refer to 3.4.1 “Mounting to fittings”.)

NOTE 1

Heated air is drawn off from the interior of the unit by fans. Before installation, consider the heat resistance of the

wall or other surfaces behind the unit. Exhaust temperatures can be 30 °C higher than the outside temperature.

NOTE 2

For wall-mounting, do not bundle the cables in a way that will obstruct ventilation.

Summary of Contents for PDP 502MX

Page 5: ...5 Features ...

Page 15: ...15 Remote Control Unit Case ...

Page 60: ...60 Plasma Display Ceiling Suspension Hardware one side type PDK 5002 ...

Page 82: ...82 Speaker System ...