PD-F957,PD-F907

40

7.2.3 ERROR HISTORY DISPLAY

(1) Disc No. A : Detail of error code at portion

<Note> The user display appears only when the normal operation cannot be returned even if the fail safe operation is executed after each

error occurs.

(2) Track No. B : Error sequence in portion

The display of 1 to 16 appears. The low number indicates the recently generated error. The error whose number is “1” was generated most

recently.

(3) Minute : Second No. C : Detail of error generation mode in portion

Indicates the internal mode in which the displayed error is generated. The upper digit in “minute : second” has the meaning.

User

display

Description

None

A0

• A disc couldn’t be detected for playback after loading because;

No disc existed.

A disc was turned upside down.

A disc was dirty.

A disc was loaded incompletely.

• The focus got out of place during playback due to the crack

and stain on the disc.

None

A1

• The servo mechanism couldn’t move to the desired tune

position within a fixed time during selection of a tune from

playback or during playback.

A3

• A disc couldn’t be loaded within a fixed time.

(A disc couldn’t be carried from the rack block.)

U1

A4

• A disc couldn’t be unloaded within a fixed time. (A disc couldn’t

be returned to the rack block.)

A2

• The LOADING mechanism couldn’t move to the desired disc

position within a fixed time during selection of a disc from

playback or during playback start from stop.

U2

A5

• The LOADING mechanism couldn’t be forcibly returned to

the home position (left position when viewed from the front)

within a fixed time after it is initialized or becomes NG.

None

A6

• A disc couldn’t be normally rotated for playback after loading

because;

A disc was turned upside down.

A disc was dirty

A disc was loaded incompletely.

• A disc couldn’t be normally rotated during playback due to the

crack and stain on the disc.

User

display

Description

None

A7

• Mechanism position just before the LOADING mechanism

shifts to the disc selection operation when the DCNT pin is

low. (The DCNT pin is usually high when the LOADING

mechanism is in the stop state. The mechanism position is

thus judged to have been shifted for some reason. The shifted

mechanism position may cause a failure.)

None

A8

• Discrepancy has occurred between the detected disc position

and the current disc position during movement of the loading

mechanism. (The system may incorrectly counted the

waveforms of the DCNT and DPOS terminals. If counting is

incorrect, the position of the disc No. displayed does not match

the disc position counted.)

None

A9

• Mechanism position during disc loading when the DCNT pin

is low. (The DCNT pin is usually high when the LOADING

mechanism is in the stop state. The mechanism position is

thus judged to have been shifted for some reason. The shifted

mechanism position may cause a failure.)

None

AA

• The pickup block cannot return to the innermost circumference

when the playback is

c

ompleted or another disc is shifted.

Digit of minute

Digit of second

Display Contents

Display Contents

0

*

Spindle stop operation

0

*

1

*

Disc return operation

2

*

Disc selection operation

3

*

Setup operation

1

*

4

*

CD-R setup operation

5

*

TOC read

6

*

Track search operation

7

*

Play

8

*

Pause

9

*

Manual search

During closing of the hood

and when the hood is com-

pletely close

During opening of the hood

and when the hood is com-

pletely open

Hood section

User

display

Description

U3

P0

The hood did not open within the specified time. The switch of

the hood was malfunctioning.

P1

The hood did not close within the specified time. The switch of

the hood was malfunctioning.

P2

The hood was attempted to be opened with force when it was

completely closed. The switch of the hood was malfunctioning.

Summary of Contents for CD-8400

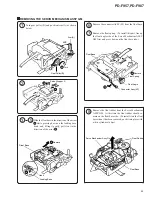

Page 9: ...PD F957 PD F907 7 2 3 LOADING MECHANISM ASSY ...

Page 54: ......