OPERATING INSTRUCTIONS

This User’s Guide is the best tool available during the initialization of your new PHX-

150 Dry Ice Cleaning System. It contains all the information necessary for the proper

installation, safety, operation, maintenance and troubleshooting right at your fingertips.

Familiarize yourself with its’ contents before operating this equipment.

CONNECTING THE AIR SUPPLY

Since the PHX-150 is an “all pneumatic” design, it is critical that only clean, dry air be

supplied to the unit. Air containing excess amounts of moisture, oil, rust, or other

contaminants may clog filters and damage the logic control and internal components. A

good desiccant or refrigerant dryer should be installed between your compressor and the

PHX-150. The dew point should not 40°F/+4.4°C. Good air quality will save

you time for repairs and increase the life of the unit.

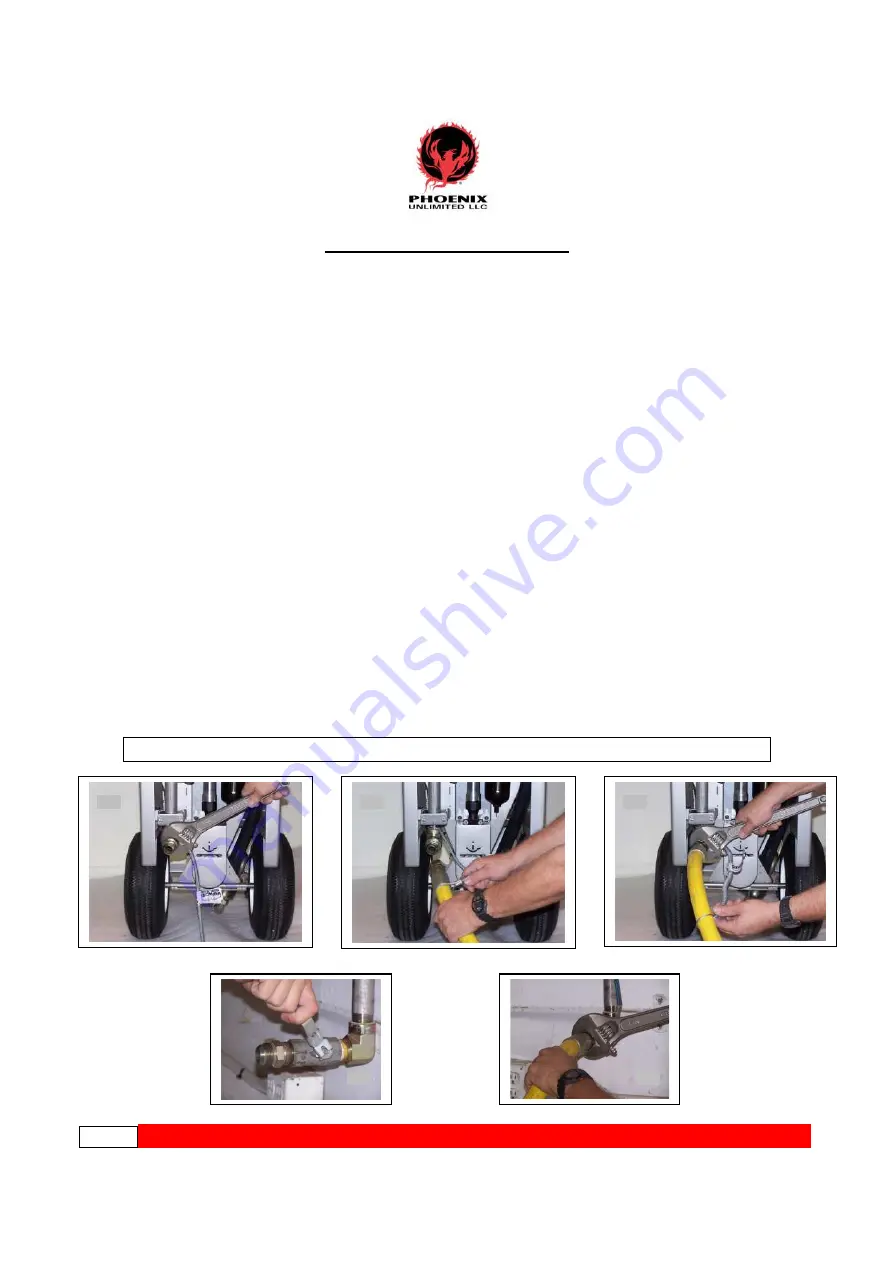

1. Install a 1” JIC/NPT male fitting into the supply inlet of the PHX-150. Be careful

with other types of common connectors as they often have gaskets or other restrictive

material, which prevent full air flow. This can drastically reduce your unit

performance level. (pic 1)

2. Install the whip check over the end of the 1” air supply hose. (pic 2)

3. Connect air supply hose to the JIC fitting and extend the whip check as far down the

hose as possible. (pic 3)

4. Wearing hearing protection, blow down the air source at the drop to remove any

accumulated moisture. This helps to insure equipment performance. (pic 4)

5. Connect the air supply hose to the air source. (pic 5)

Caution! Maximum air pressure supplied to the PHX-150 should never exceed 125 psi!

Page 10

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

P

P

H

H

X

X

-

-

1

1

5

5

0

0

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

Pic 1

Pic 2

Pic 3

Pic 4

Pic 5