30198-004b 5

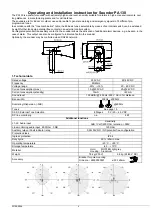

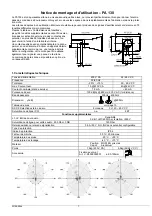

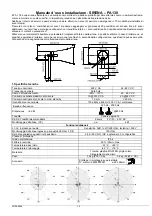

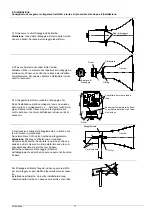

2. Mounting

We recommend making the electrical connection at the base before assembling the device.

2.1 Release fixing screws from the horn.

Caution

: The two fixing square nuts inside the horn are

not fixed in place. Hold them in place when removing the

screws.

2.2 Remove the horn.

Fix the driver system to the horn. Position the driver

so that in fully mounted state, the sounder bleed hole

faces downwards. For this purpose, use the distance

washer included in the accessories kit.

2.3 Electrical connection (see also page 6).

Following electrical installation, connect the cable

from the pcb to the + or - connection on the driver

(see fig.). Also connect the temperature sensor to the

center of the driver with the adhesive strip included in

the accessories kit.

Finally, connect the housing and horn with the previ-

ously removed screws.

Do not forget the O-ring between the horn and the

housing.

Caution: In certain cases, condensate may form in-

side the sounder. For this reason, ensure that one of

the two bleed screws (A or B) has been removed and

that the opening faces downwards.

Make sure that both bleed holes (in the housing and

in the driver) face downwards.

For fixing, the supplied bracket or the pole bracket

(available as option) may be used.

Outdoor installation: The horn opening must not point

upwards following installation of the sounder.