34

18.3

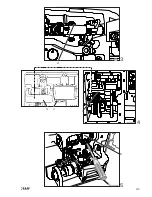

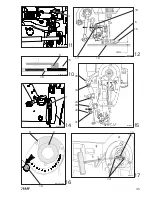

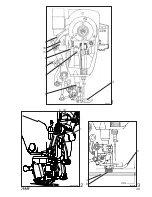

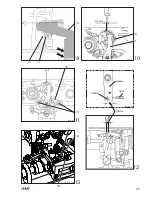

Top feed - lifting motion

Requirement:

with:

- stitch length 4 mm

- cam setting “0”

- connecting rod 4 (fig. 11) attached

the top feed 5 (fig. 12) must touch the bottom feed dog when the bottom

feed dog reaches the top edge of the needle plate on its way up (fig. 13).

.1

Remove the face cover.

.2

Set the stitch length at 4 mm (stitch length adjustment lever 7; fig. 14).

.3

Attach connecting rod 4 (fig. 11).

.4

Set control cam 8 (fig. 16) at “0” (turn cam carrier 9 on its shaft).

Note:

The actuating lever 10 must have a little bit of play when the control cam is set at “0”;

(see arrow in fig. 16).

.5

Adjust in accordance with the requirement: eccentric 13 (fig. 17; screws 14).

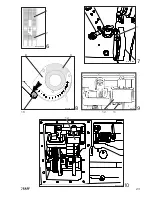

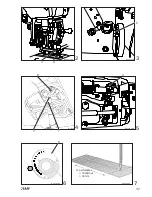

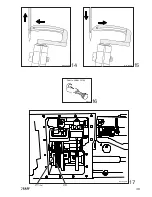

18.4

Top feed - stroke

Requirement:

when the stitch length is set at 4 mm,

- the presser foot 15 (fig. 12) is touching the needle plate 16 and

- the top feed 5 is at its t.d.c.,

the distance between the top edge of the needle plate 16 and the bottom edge

of the top feed should be 3 mm.

.1

Set the stitch length at 4 mm (stitch length adjustment lever 7; fig. 14).

.2

Bring the top feed 5 (fig. 12) to its t.d.c. (handwheel)

.3

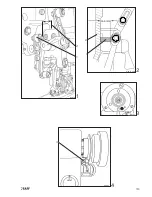

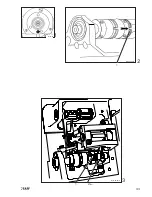

Position the top feed parallel to the needle plate (pin 17, screw 18). Basic position of the pin 17

(fig. 12): with the eccentricity away from the machine.

.4

Position pin 19 (fig. 15) at the bottom of the elongated hole (nut) in the connecting lever 20.

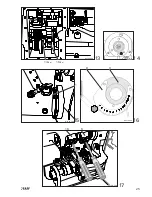

.5

Set the clearance at 3 mm.

.5.1

Basic position of the eccentric pin 21 (fig. 15): eccentricity facing downwards (screw 22).

.5.2

Rough adjustment: loosen screw 23 and move actuating lever 24 (arrow in fig. 15) so that a distance

of 3 mm exists between the top feed 5 (diag 12) and the needle plate 16.

.5.3

Fine adjustment: eccentric pin 21 (screw 22).

.6

Tighten all the screws.

Summary of Contents for 3811-11/43

Page 9: ...9 1 1 2 3 1 Bi34 01 CDR 2 4 3 Bi03 03 CDR ...

Page 11: ...11 4 1 Min Oil level Max Oil level 1 2 Bi08 01 Bi18 05 Bi08 04 CDR Bi02 01 3 ...

Page 13: ...13 3 2 1 4 1 Bi11 01 CDR 2 3 Bi11 02 Bi11 04 Bi11 03 ca 7cm ...

Page 15: ...15 2 Bi12 02 CDR Bi12 03 CDR 3 6 1 2 4 5 1 3 Bi12 01 CDR ...

Page 17: ...17 4 Bi14 04 5 Bi14 05 Schematic diagram 7 6 Bi14 03 3 6 4 5 7 4 7 5 0 8mm Bi14 02 CDR 2 3 ...

Page 19: ...19 Bi01 01 1 1 2 Bi16 02 CDR 11mm Bi14 03 3 1 2 ...

Page 21: ...21 5 Bi17 03 CDR 3 4 Bi17 04 CDR 2 Bi17 03 3 4 4 Bi17 05x CDR 5 ...

Page 27: ...27 18 Bi17 18 CDR 19 2x 18 17 20 2x 20 Bi17 20 CDR 17 19 2x 18 20 2x 19 Bi01 01 1 ...

Page 31: ...31 Bi18 16 Bi18 05 4 1 4 Bi01 01 16 5mm Bi18 17 CDR 3 2 2 1 3 1 2 ...

Page 39: ...39 Bi14 03 1 Bi14 03B 7mm 2 3 4 2 3 1 9 8 7 11 5 Bi20 03 CDR 10 10 5 1 6 ...

Page 43: ...43 1 Bi01 01 1 3 Bi17 20 CDR Bi20 02 CDR 1 2 1 2 2x ...

Page 49: ...49 Bi21 15 CDR 14 15 Bi21 16 CDR 16 Part No 08 880 137 00 Bi21 17 17 Bi17 04 CDR 20 21 2x ...

Page 51: ...51 Bi21 18 CDR 18 1 0 1 2mm Bi14 03 22 23 20 19 Bi21 19 CDR 0 1mm Hook ...

Page 53: ...53 Bi22 21 CDR Bi21 11 2 1 2 1 1 Bi01 01 3 3 Bi22 04 CDR 4 Bi22 05 5 6 Bi22 06 3 4 6 7 5 ...

Page 55: ...55 Bi24 01 CDR 1 2 Bi22 06 2 1 1 4 3 5 2 Bi24 04 CDR 0 3 0 5mm 3 4 1 ...

Page 57: ...57 0 3mm Bi25 01 1 1 2 Bi26 01 Bi26 02 2 3 3 1 3 4 Bi27 01 4 5 ...

Page 59: ...59 Bi29 04 CDR 5 4 1 3 4 Bi29 03 CDR 8mm 3 Bi28 01 1 1 2 5 4 3 6 Bi01 01 1 2 29mm ...

Page 63: ...63 7 6 5 Tastenfeld von 11 43 11 45 13 45 Bi31 02 CDR Bi19 04 CDR ...

Page 69: ...69 1 Bi33 01 CDR 3 1 2 4 Tastenfeld 11 43 11 45 13 45 2 Bi02 03 CDR ...