Adjustment

13 - 8

13

.06.05

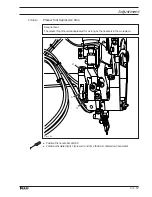

Hook shaft bearing and hook-to-needle clearance

Requirement

1. The groove in bearing

3

(see arrow) should be visible from below and there should be

slight but palpable play between gear wheels

5

and

9

.

2. When the hook is resting lightly on the centrifugal disk and the hook point is positioned

at the center of the needle, there should be a clearance of

less than 0.1 mm

between

the hook point and the clearance cut of the needle.

3. Gear wheel

5

should align with gear wheel

9

.

Fig. 13 - 07

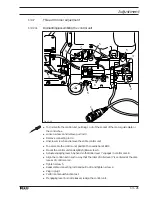

●

Loosen screws

1

and

2

.

●

Turn bearing

3

according to the

requirement 1

.

●

Move the hook gently against centrifugal disk

4

until it stops.

●

Move bearing

3

without turning it according to

requirement 2

.

●

Tighten screws

1

and

2

.

●

Move gear wheel

5

(screw

6

) according to

requirement 3

.

9

5

6

3

1

2

4

<0.1 mm