19

Introduction

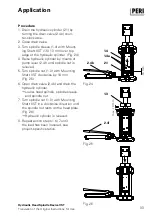

Hydraulic Head Spindle Device VST

Translation of the Original Instructions for Use

4. Inspection

4.1 Safety check

It must be verified whether all defects

have been rectified or non-functioning

products have been replaced.

4.2 Implementing the inspection

The inspection includes a visual and

functional check:

– deformation, wear and lengthening of

the components.

– damage due to corrosion.

– mechanical damage.

– availability of all components.

– cracks, bending, flattening, notches on

welding seams and components.

– only original PERI components may be

used.

– indications of inpermissible heating or

contact with fire.

– markings must be legible.

4.3 Functional check

Free and easy movement of moving

parts.

Implementation of anything beyond the

usual scope of inspection is subject to

the discretion of the qualified person and

can extend to additional checks.

4.4 Measures

If any defects are determined during the

safety inspection, they must be eliminat-

ed according to the instructions provided

by the qualified person. A new inspec-

tion is to be subsequently carried out.

4.5 Inspection before starting work

operations

– Check load-bearing capacity.

– Check hydraulic components.

EN_BA_Hydr_Kopfspindeleinheit_VST.indb 19

01.04.16 11:25

Summary of Contents for 117465

Page 27: ...25 Hydraulic Head Spindle Device VST Translation of the Original Instructions for Use...

Page 44: ...42...

Page 45: ...43...