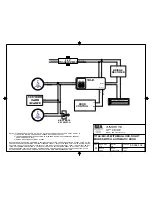

5

INTERIOR SEAL

Caution: Ensure use of low pressure polyurethane window and

door installation foams and strictly follow the foam manufacturer’s

recommendations for application. Use of high pressure foams or improper

application of the foam may cause the door to bow and hinder operation.

A.

Apply insulating foam.

From the interior, insert the nozzle of the applicator

approximately 1" deep into the space between the door and the rough

opening and apply a 1" deep bead of foam. This will allow room for

expansion of the foam and will minimize squeeze out. Apply sealant across

the interior surface of shims to create a continuous seal. Follow foam

manufacturer's instructions. For doors with jamb extensions installed, ensure

the foam is placed between the door frame and the and the rough opening,

not between the jamb extension and the rough opening.

Note: DO NOT apply foam to the lower 6" of each jamb. (see 5D).

Note: DO NOT completely fill the space from the back of the brickmould

to the interior face of the opening.

Note: You may need to cut excess foam out of the lock strike.

B.

Check the door operation by opening and closing the door.

Note: If the door does not operate correctly, check to make sure it is still

plumb, level, square and the sides are not bowed. If adjustments are

required, remove the foam with a serrated knife. Adjust the shims and

reapply the insulating foam sealant.

Interior

4A

4D

6"

5C

5C

C.

Add a sealant bead across the inner sill

and 6" up each jamb

between the frame

and rough opening and tie in with the

foam sealant application.

D.

Apply interior trim as desired.

Note: Use backer rod between the frame jamb and opening 6" up each

jamb in accordance with sealant manufacturer's instructions.