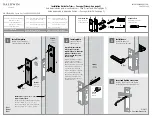

O.

If needed, the height of the threshold can be

adjusted

to achieve appropriate contact with

the door sweep. Remove screw cover caps as

necessary and use a #3 Phillips screwdriver to

turn the adjustment screws clockwise to lower

the threshold or counter-clockwise to raise the

threshold.

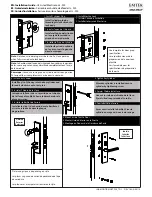

P.

Place a 1/4" bead of sealant

along the corners

where the sill meets both side jambs.

Q.

Before the sealant sets up;

remove paper

backing from the corner seal pad and position the

pad embedded in the sealant and tight against the top of

the adjustable threshold, with the thin portion of the pad

flush with the interior face of the jamb (both jambs).

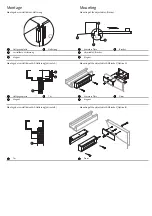

R.

Install handle and lock hardware.

Refer to manufacturer’s

instructions included with the hardware.

Note: At this time, install any additional fasteners if

needed to meet local code requirements such as those

required to comply with the Florida Building Code.

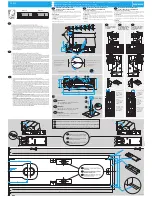

3S

3S

Front View

Interior

3O

Exterior

Remove paper

backing from the

corner seal pad

3Q

3P

S.

Apply 1/4" bead of sealant where each sidelight jamb meets the

sidelight sill

and around the exterior mullion cover where the door and

sidelight frame are joined together.

3

SETTING AND FASTENING

THE DOOR (CONTINUED)