F.

Fasten the door to opening

by driving 2” galvanized

roofing nails into each

pre-punched hole in the

nailing fin.

Note: Make sure the fin

corner is lying as flat as

possible.

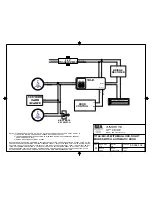

Exterior

3H

3F

Interior

3K

3J

G.

carefully open the door(s)

and remove all

shipping spacers.

Note: Be sure to remove the spacers from the

bottom edge of the door panel.

Double doors with center latch:

Designer Series only:

Use the construction

handle to operate the active door handle.

Operate the flushbolts per the instructions on

the label on the strike located on the astragal.

architect Series only:

Use the construction handle to operate both the active and passive

door panels.

H.

For Designer Series only:

Install sill screws. Place a dab of sealant in each of the pre-

drilled holes in the bottom of the unit (sill). Then insert a #8 x 2” corrosion resistant screw

(provided) into each hole. For masonry floors us a 3/16” masonry screw in place of the

provided screw, pilot drill per screw manufacturer’s recommendations.

For architect Series Standard Installation applications only:

Install sill screws. Remove

the threshold screws and insert a #8 x 3” stainless steel screw (provided) into each hole. For

masonry floors use a 3/16 masonry screw in place of the provided screw, pilot drill per screw

manufacturer’s recommendations.

SILL ScREWS FOR ARcHITEcT SERIES PERFORMANcE UPgRADE AND

DOORS WITH HURRIcANESHIELD IMPAcT-RESISTANT gLASS ARE

INSTALLED IN STEP 5.

I.

For Low profile Sills: through each installation

screw hole drill a 1/8” pilot

; and install a #8 x 3”

corrosion resistant screw (provided) into the pilot

hole into the floor. For doors including a standard

lock install tubs per instruction included with the

sill strike package.

Note: For concrete floors use masonry screws that

are a minimum size of 3/16” diameter x 2” and

pilot per manufacturer’s recommendations for

the screw.

J.

remove sill strike screws from the sill strike

located on the door sill.

Place a dab of sealant

into the three sill strike holes and install the three

#8 x 3” flat head stainless steel screws (provided)

into the holes.

DOORS

•

ALL

DOORS

•

ALL

DOORS

•

ALL

DOORS

•

ALL

DOORS

•

ALL

DOORS

•

ALL

DOORS

Note: On In-Swing Door Standard Installation, sill screws are not needed.