For DoorS USIng optIonaL SILL pan go to Step 1I.

Exterior

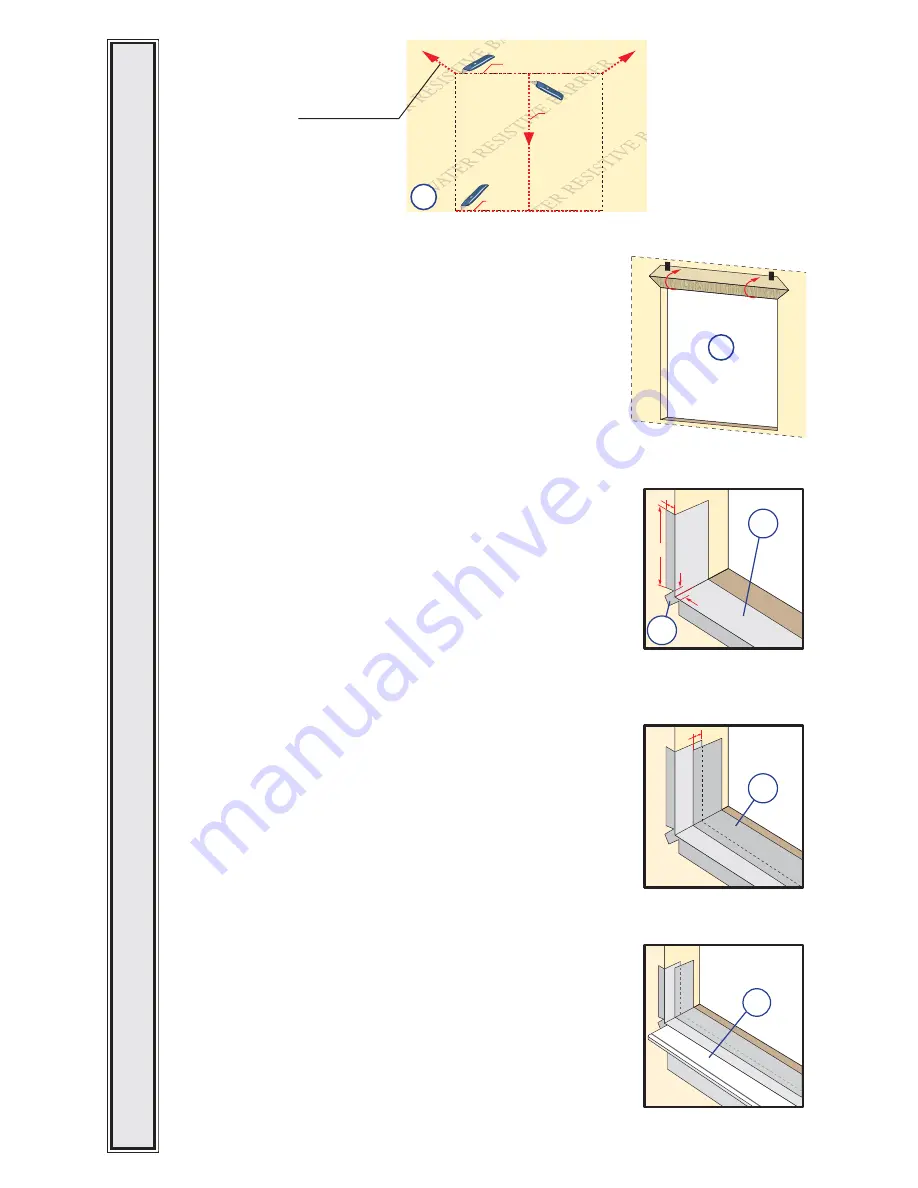

1D

4th cut:

Make a 6" cut up from

each top corner at a 45

o

angle to allow the water

resistive barrier to be lapped

over the fin at the head of

the door.

1st cut

2nd cut

3rd cut

Water Resistive Barrier

1C

C.

cut the water resistive barrier.

D.

Fold the water resistive barrier.

Fold side flaps into the opening

and staple to inside wall. Fold top flap up and temporarily fasten

with flashing tape.

E.

apply sill flashing tape #1.

Cut a piece of flashing tape 12” longer

than the opening width. Apply at the bottom of the opening as

shown (IE) so it overhangs 1” to the exterior.

Note: The tape is cut 12” longer than the width so that it will

extend 6” up each side of the opening.

F.

tab the sill flashing tape and fold.

Cut 1” wide tabs at each corner

(1/2” from each side of the corner) (1F). Fold tape to the exterior

and press firmly to adhere it to the water resistive barrier.

1F

1"

1/2"

1/2"

6"

1E

1"

1G

G.

apply sill flashing tape #2.

Cut a piece of flashing tape 12” longer

than the opening width. Apply at the bottom, overlapping tape #1

by at least 1”. DO NOT allow the tape to extend past the interior

face of the framing (1G).

In-swing doors:

If the wall depth is greater than 5”, add a third piece of flashing

tape. The flashing tape should come to within 1” of the interior face

of the framing.

Note: The flashing tape may not fully cover the framing members.

1H

H.

attach the aluminum sill support

or wood blocking to the exterior

of the box plate to support the edge of the door sill. Place the sill

support flush with the subfloor.

go to Step 2

DOORS

•

ALL

DOORS

•

ALL

DOORS

•

ALL

DOORS

•

ALL

DOORS

•

ALL

DOORS

•

ALL

DOORS