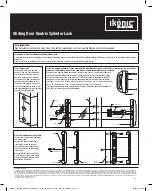

applications for performance Upgrade and HurricaneShield:

6"

16" MAX

O.C.

16" MAX

O.C.

16" MAX

O.C.

16" MAX

O.C.

6"

6"

6"

6"

6"

6"

6"

DOUBLE OPERABLE

6"

6"

16"

MAX.

O.C.

2C

6"

6"

16"

MAX.

O.C.

2C

2C

5E

16" MAX

O.C.

16" MAX

O.C.

6"

6"

6"

6"

SINGLE FIXED OR OPERABLE

6"

6"

16"

MAX.

O.C.

6"

6"

16"

MAX.

O.C.

2C

2C

2C

5E

DIAGRAM FOR

PLACEMENT OF

THRESHOLD SCREWS &

INSTALLATION CLIPS

C.

Doors using Installation clips:

Install

installation clips. Place each clip so

the lip is facing up and against the

installation fin at the locations shown

in the placement diagram. Secure each

clip by driving a #6 x 5/8” corrosion

resistant screw through each of the

outer two holes of the three holes

shown.

Note: If clips are to be bent; pre-bend

before attaching to frame.

6“ from end

Lip

#6 x 5/8” corrosion

resistant screws

2C

3

SETTINg AND

fASTENINg

THE DOOR

A.

place three 3/8” beads of sealant.

Place the first beads sealant ½” from

the base of the interior sill pan lip.

This bead should also continue up the

corner of the sill pan at each end, sealing the vertical

joints of the sill pan legs. Continue the first bead up

6” onto each jamb side of the rough opening. The

second bead should be approximately ½” from the

exterior edge of the rough opening, running from

jamb to jamb with a 2” break in the middle of the

opening. Place a third sealant bead in the groove

of the sill support from end to end or ¼” from the

exterior edge of the wood blocking.

Note: Sill sealant detail is the same for applications

with and without optional sill pan.

3A

1

2

3

6”

PERFORMANCE UPGRADE & HURRICANESHIELD DOORS

ALL

DOORS

•

ALL

DOORS

EXTERIOR SILL P

AN LIP

INTERIOR SILL P

AN LIP

2nd Bead

Leave a 2" break

in center of pan

1st Bead

3rd Bead

3A

6”

Out-Swing Vent or Fixed

In-Swing Vent

Out-Swing Vent or Fixed

In-Swing Vent

Out-Swing Vent and Fixed

In-Swing Vent

Screw

Location

Screw

Location

Applications without sill pan