L.

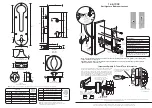

Bend each end of the center

panel up.

J.

Make a 1" cut in each fold

at both ends of the sill pan.

Note: These cuts will allow the edges of the sill pan to be bent.

K.

Cut 1" off each end of the

interior sill pan lip.

M.

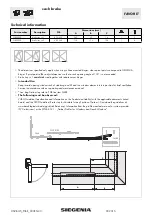

Install the sill pan by sliding

into place

until the exterior sill

pan lip is fl ush with the exterior

of the rough opening.

N.

Apply sill fl ashing tape.

Cut a piece

of fl ashing tape 2" longer than the

opening width. Apply at the bottom of the

opening, covering the exterior sill pan lip

as shown.

Note: If applicable, apply spray

adhesive to building felt prior to

applying the fl ashing tape.

O.

Cut two 9" pieces of fl ashing tape

with a 1" x 3"

tab at the bottom, on opposite corners as shown.

P.

Apply the tabbed 9" pieces of fl ashing tape.

The tape is applied so 2" will cover the inside of

the rough opening and lap over the side fl ange

of the sill pan. The 1" x 3" tab laps over the

bottom fl ashing tape as shown.

&95&3*034*--1

"/-*1

'MBTIJOH5

BQF

4JEF

'MBOHF

-

&95&3*034*--1

"/-*1

'MBTIJOH5

BQF

.

Q.

Cut two 6" pieces of fl ashing tape

and

apply to each side of the rough opening,

overlapping the fi rst piece by 1" and

lapping the bottom over the side fl ange of

the sill pan as shown.

R.

Cut a piece of fl ashing tape to the width of the opening.

Install to the fl anges of

the sill pan and overlap the tape from step 1N by 1”. If needed add a second or third

piece of fl ashing tape until the sill pan is covered to the interior sill pan lip.

Note: The purpose of this tape is to seal the sill screws when installing the door.

S.

Cut two pieces of fl ashing tape

1-1/2" x

6" and apply to the bottom corners of the

opening by beginning in the corner of the sill

pan, with 3/4" of the tape applied to the sill

pan and 3/4" of the tape applied to the side

fl ange. The remainder of the tape is to be at a

45 degree angle onto the exterior.

Optional Sill Pan Instructions.

DOORS •

ALL

DOORS •

ALL

DOORS •

ALL

DOORS •

ALL

DOORS •

ALL

DOORS •

ALL

DOORS

*/5&3*034*--1

"/-*1

&95&3*034*--1

"/-*1

(

1K

*/5&3*034*--1

"/-*1

&95&3*034*--1

"/-*1

)

1L

Exterior

1M

EXTERIOR SILL P

AN LIP

Install flush

against exterior

rough opening.

1N

EXTERIOR SILL P

AN LIP

Flashing T

ape

Weather Barrier

1M

1N

9"

3"

1" Tabs

3"

2"

9"

1" Tabs

3"

2"

1O

1O

1P

1Q

Note: 4-5/8" wide for Out-swing and In-swing for 4-9/16" wall condition. For

other wall conditions; measure wall depth and add 1/16".

I.

Cut the sill pan

to the width of the rough opening plus 2".

Note: The 2" added onto the rough opening width is for a 1" bend on each end.

INTERIOR SILL P

AN LIP

EXTERIOR SILL P

AN LIP

1"

1"

Variable

1J

1"

1J

EXTERIOR SILL P

AN LIP

INTERIOR SILL P

AN LIP

1R

1S

1"