5

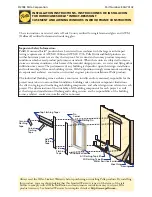

EXTERIOR SEAL

A.

Place a corner bead of sealant at the jambs and head

connecting the existing frame and the replacement

window frame.

Caution: DO NOT seal the bottom exterior to allow for

incidental water to weep.

5A

1”

5B

Sill

5A

B.

Optional: Place a bead of sealant

where the sill

adapter meets the sill. If sealant is placed on the sill

leave at least 1” of sill adapter unsealed at each end.

This sill allow for incidental water to weep.

POCKET REPLACEMENT

'ŽƚŽƉĂŐĞϭϭĂŶĚϭϮĨŽƌ/ŶƚĞƌŝŽƌĂŶĚdžƚĞƌŝŽƌ&ŝŶŝƐŚŝŶŐ/ŶĨŽƌŵĂƟŽŶ͘

FIXED WINDOW REPLACEMENT:

FIXED WINDOW REPLACEMENT

6

FIXED SASH REMOVAL

I

N

TERIOR SASH STOP

1A

Interior

sash stop

1A

1A

Note: Confirm the opening and window dimensions prior to removing the

existing window sash.

A.

Score paint or varnish along

interior sash stops

with sharp

utility knife. Carefully remove the

interior sash stops at jambs (sides)

and head (top) using a putty knife

and pry bar. Set aside for reuse.

B.

Remove the old sash.

Remove

other trim, stops, flashing or

brickmould as required.

6A

6A

C.

Clean opening thoroughly

and repair or replace any rotted or

damaged framing if required.

Note: The end result should be a clean flat uninterrupted surface

on the bottom, top and sides of the opening where the new window

will be installed.

D.

Test fit the window,

make any adjustments to opening as needed.

6A