LED display and keyboard. Speed testing and

positioning system consist of gearbox and

electronic clutch. Horizontal and vertical

pressure sensors.

The workplace

Choose a workplace in accordance with statutory

safety regulations. The machine requires a free

working surface of at least 500 mm to the nearest

wall on the left and behind and 700 mm on the

right side. Place the machine on a stable and

stable floor, use a spirit level to check that the

machine is level. Drill four holes in the floor and

mount the machine with an expander bolt and

tighten with a fixed wrench.

Introduction of the display control panel

1. Digital reading, amount of imbalance, inside

2. Digital reading, amount of imbalance, outside

3. Balancing mode

4. Pushbuttons, manual DISTANCE setting

5. Pushbuttons, manual WIDTH setting

6. Pushbuttons, manual DIAMETER setting

7. Show real imbalance amount (less than 5

grams), function key 1gram / ounce 2mm / inch

3-calibration

8. Push button, recalculation

9. Function key for selecting balancing mode

10. Show imbalance position outside

11. Show imbalance position on the inside

12. Push button, optimization of imbalance

13. Split function

14. Indication of optimization

15. Indication of the ALU-S mode

16. Information about division

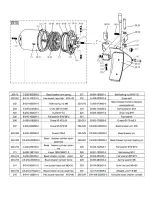

Assembly and disassembly of wheels

Before mounting the centering cone on the

machine’s balance shaft, check that the surfaces

of the centering cone and the balance shaft are

clean, no sand or dirt, and that the tire is also clean.

Remove any previous balance weights, check the

air pressure and that the rim is not damaged. Then

fit the appropriate centering cone. Mount the wheel

on the balance shaft and fasten with the quick nut.

Remember that poor centering leads to

unnecessary imbalance.

Placement of centering cone in most cases of

aluminum rims. (To protect the rim on the outside

against the quick nut). Positive positioning is

commonly used. It works easily and is useful for

different types of sheet metal rims and thin

aluminum rims. Placement of centering cone in

most cases of sheet metal rims. Negative

positioning is used to protect the inner hole of the

rim and the main axle is positioned exactly even if

the outside of the wheel is deformed. Used for all

sheet metal rims, especially thick sheet metal rims.

Disassembly of wheels

Release the quick nut by turning it

counterclockwise and then release it with the red

levers. Remove the cone and lift the wheel, being

careful not to scratch the balance shaft.

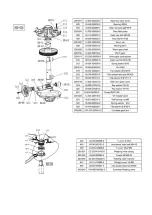

Programming of rim data

(done in different ways depending on the mode)

Switch on the main power - the machine starts up

automatically and is ready after 2 seconds. The

machine automatically adjusts position and is

ready for input data about the rim.

Summary of Contents for 498192

Page 1: ...Tyre changer balancer 2 in 1 D ckmaskin balanserare 2 i 1 Item No 498192...

Page 11: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 33: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......