8 / 14

SAR

AUTOMATIC STATIONS FOR WASTE WATER

COLLECTING AND LIFTING

INSTALLATION AND USE MANUAL

Ed. 01 Rev. 01

02/02/2007

SAR stations are designed for pumping sewage in installations below the sewer level. The reservoir

capacities are 40, 100, 250 and 550 litres and all the reservoirs are equipped with seal covers to

prevent liquid or gas leakages.

The liquid temperature may reach +40°C, a limit imposed by the submersible motor-driven pumps

contained in the reservoirs. The use is not allowed in environments with explosion hazards and for

pumping inflammable liquids.

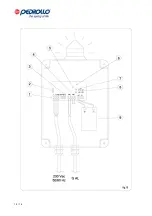

Components of the SAR40, SAR100 and SAR250 stations:

-

40, 100, 250 litre polyethylene reservoir, respectively

-

1 submersible single-stage motor-driven pump with floating switch and 5-metre power supply

cable with Schuko plug.

-

various joints for input, output and bleeding pipes

-

non-return valve (SAR40 only)

-

300-metre extension for reservoir opening (optional for SAR250 only)

-

self-powered panel with horn, flashing light and alarm float (optional).

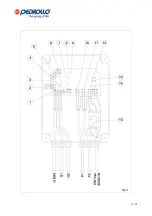

Components of the SAR550 stations:

-

550 litre polyethylene reservoir

-

2 submersible single-stage motor-driven pumps with 5-metre power supply cable

-

3 floats with minimum level, maximum level and pump alternation functions

-

various joints for input, output and bleeding pipes

-

non return valve and stop valves

-

guiding pipes for pump lowering (only for VX-I)

-

300-metre extension for reservoir opening (optional)

-

control panel

-

self-powered panel with horn, flashing light and alarm float (optional).

1 – WARNINGS AND SAFETY

8.

Read the hereunder use manual and the motor-driven pump manual before installation.

9.

The system installation and the connection of the electric panels must be carried out by qualified

personnel and in compliance with the laws in force.

10.

The installation location must guarantee easy access to the system for inspections and

maintenance, if required.

11.

The electric panels must be connected to an efficient grounding system in compliance with the

laws on electricity in force; set up the grounding connection as the first operation.

12.

Any maintenance operation on the electric and mechanical parts of the system must be carried

out after interrupting the power supply.

13.

System maintenance must be carried out exclusively by qualified personnel in compliance with

the accident-prevention laws in force.

14.

The final system installer is in charge of setting all the necessary measures to make the system

compliant with safety regulations.

2 – TANK INSTALLATION

The tank may be placed on the floor, earthed or located in a brick pit. At any rate the bearing plane of

the tank must be perfectly horizontal and the bottom of the tank must lay on the whole surface.

The tank is provided with the pump and the pre-assembled floats. The length of float cables is set in

order to guarantee the correct operation of the system.

Summary of Contents for SAR100

Page 2: ...2 14 INDEX ITALIANO pag 3 ENGLISH page 8 LEGENDA KEY page 13...

Page 13: ...13 14...

Page 14: ...14 14...