MN-36956/MM-1074

Rev 0 (01/15) • Blanket Warming Cabinet Operation & Care Manual • 20

NOTE:

If your unit is not operating properly, check the following before calling your authorized service agent . Check the power applied to the unit .

Verify female end of plug is securely seated in unit and that the male end of plug is in an appropriate, functioning outlet . Check fuses . (See “Fuse

Replacement” section in manual .)

Do not attempt to repair or service beyond this point . Contact manufacturer for nearest authorized service agent . Repairs made by any other

service agent without prior authorization by manufacturer will void the warranty on the unit .

This chart is provided for the assistance of qualified technicians only and is not intended for use by untrained or unauthorized service personnel .

Blanket warmer temperature may fluctuate

±

10° from set point .

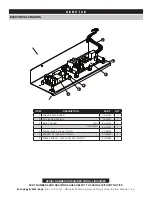

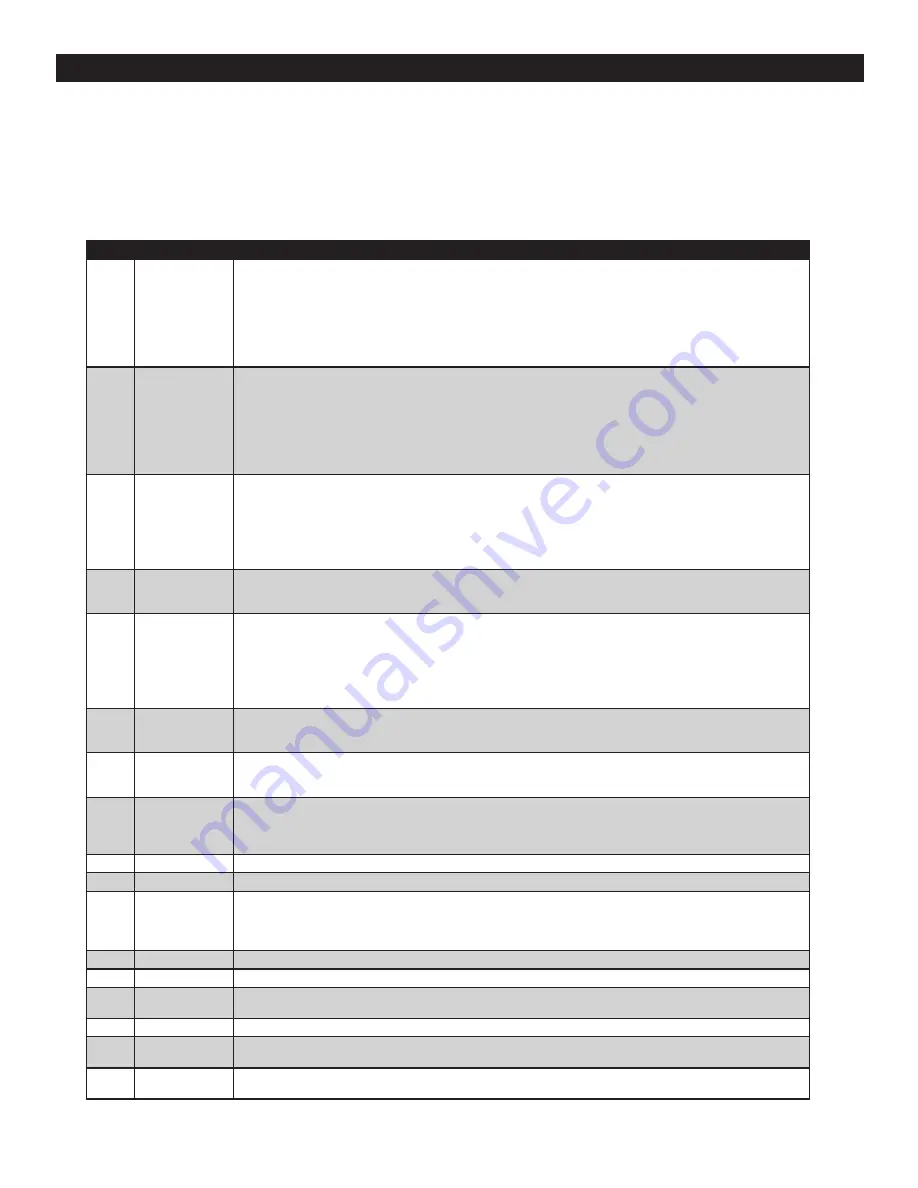

T R O U B L E S H O O T I N G G U I D E

Code

Refers to

Action Required

E-10

ES10

ES20

ES30

ES40

ES50

ES60

ES70

Cavity sensor

Sensor 1

Sensor 2

Sensor 3

Sensor 4

Sensor 5

Sensor 6

Sensor 7

Sensor is shorted . Software disengages heating pads . User must acknowledge error by pressing ON/OFF button . If

error persists, a qualifi ed service technician should test sensor.

• To test sensor: Detach the sensor from unit . Use an Ohm meter to measure the resistance of the sensor . Check

sensor at 0°C (32°F) using a container of ice water . If reading is 32 .6 KOhm ±1 .5 KOhm, replace display . If reading

is ±2 KOhm, replace sensor .

• Check wires for integrity . Check for proper and secure connections at the control and terminal block . If necessary,

re-secure the faulty connections .

• Call service if error persists .

E-11

ES11

ES21

ES31

ES41

ES51

ES61

ES71

Cavity sensor

Pad sensor 1

Pad sensor 2

Pad sensor 3

Pad sensor 4

Pad sensor 5

Pad sensor 6

Pad sensor 7

Sensor is open . Software disengages heating pads . User must acknowledge error by pressing ON/OFF button . If error

persists, a qualifi ed service technician should test sensor.

• To test sensor: Detach the sensor from unit . Use an Ohm meter to measure the resistance of the sensor . Check

sensor at 0°C (32°F) using a container of ice water . If reading is 32 .6 KOhm ±1 .5 KOhm, replace display . If reading

is ±2 KOhm, replace sensor .

• Check wires for integrity . Check for proper and secure connections at the control and terminal block . If necessary,

re-secure the faulty connections .

• Call service if error persists .

P130

P230

P330

P430

P530

P630

P730

Pad 1

Pad 2

Pad 3

Pad 4

Pad 5

Pad 6

Pad 7

Heating pad has not reached set-point temperature . User must acknowledge error by pressing ON/OFF

button. If error persists, a qualifi ed service technician should test the heater pad(s).

• Turn unit OFF and unplug it from AC power .

• Use Ohm meter to measure resistance between L:(Line) & N:(Neutral) leads of a cold heater pad .

–

The Ohm readings shall be: 120V = 72 Ohm ±10% or 230V = 288 Ohm ±10%

• Call service if error persists .

*E-31

Cavity sensor

• Sensor reading is above maximum allowable temperature set-point .

–

Fluid Warmers, triggers at 5° over set point . Blanket Warmers, triggers at 15° over set point

• Call service .

P131

P231

P331

P431

P531

P631

P731

Pad sensor 1

Pad sensor 2

Pad sensor 3

Pad sensor 4

Pad sensor 5

Pad sensor 6

Pad sensor 7

Heater pad over-temp error

• Software disengages heating pads .

• User must acknowledge error by pressing ON/OFF button .

• Allow unit to cool .

• Call service if error persists .

*E-33

Cavity sensor

• Sensor reading is above maximum allowable temperature set-point and over temp value

–

Fluid Warmers, triggers at 71°C (160°F) . Blanket Warmers, triggers at 79°C (175°F)

• Contact service

*E-50

Analog to Digital

Convertor Error

• Remove product and allow unit to cool down. Inspect fl uid and discard if necessary.

• If error persists after cool down and reset, control assembly should be replaced by a qualifi ed service technician.

Contact service .

E-60

Real Time Clock

Checksum Error

(Blanket Warmers Only)

Real Time Clock rechargeable battery backup has discharged .

• Plug unit into outlet for 30 minutes .

• See “Timer Control Panel” section in blanket manual to reset clock .

*E-61

Real Time Clock

(Blanket Warmers Only)

Real Time Clock not responding . Call service if error persists .

E-62

Real Time Clock

Timer overlay is present, but no real time clock is detected . Call service .

*E-70

Pad Count Error

More heater pads detected than set for . Hold ON/OFF button for 12 seconds until display shows "PAd#”

(# = number of pads selected [3-7]) . Press UP or DOWN arrow to adjust to correct number of pads .

–

Fluid Warmers: DC250L & DC400L = 3 pads

–

Blanket Warmers: DC150, DC250, & EC250 = 3 pads, DC350, DC400, EC350, DC750 & EC750 = 4 pads

*E-71

Personality Error

Call service

E-80

EEPROM Error

EEPROM not responding . Call service if error persists .

*E-81

Calibration

not locked

Call service

*E-83

EEPROM Error

Call service for help resetting the control .

E-87

EEPROM Error

Stored offsets corrupted . Offsets reset to 0 . Control may need to be recalibrated . Possible bad EEPROM .

Call service if error persists .

E-90

Button stuck

A button has been held down for >60 seconds . Adjust control . Error will reset when the problem has

been resolved .

E-95

Factory Test pin

short detected .

Ensure no debris is causing a short between the test pins . If pins are good, replace control .

*E-98

Temperature

Delta Error

(Fluid Warmers Only)

Temperature of cavity sensors 1 and 2 differ by more than 1 .7ºC (3ºF) .

• Remove product and allow unit to cool down .

• Verify that product sensor is clean and operating correctly .

• Press power button to clear error code .

• If error persists, the sensor switch assembly should be replaced by a qualified service technician. Contact service.

E-99

Hardware

Over Temp

• Inspect connections and condition of high limit bimetal thermostat .

• If error continues call service .

*EFAn

Fan or Fan Sensor

failure

(Fluid Warmers Only)

• If the fan is operating, ensure that the lens on the sensor is not blocked or dirty .

• If error persists after cleaning sensor, use an Ohm meter to ensure sensor wires are good . A good wire will have a

reading of <1 Ohm .

• If wires are good, replace sensor .

• If error persists after replacement, check sensor mount location .

• If error still persists, replace control .

Note:

All non-critical codes can be cleared using the ON/OFF button . Critical errors (marked with a *) can only be cleared by turning the power switch

on the back of the unit off and allowing unit to cool .