MN-36956/MM-1074

Rev 0 (01/15) • Blanket Warming Cabinet Operation & Care Manual • 16

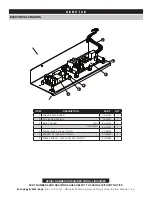

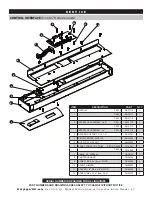

UP

button

DOWN

button

ON/OFF

button

Button lockout

indicator light

Overtemp

indicator light

Control and LED Display

TEMPERATURE

RECALL button

CONTROL PANEL BUTTONS

ON/OFF BUTTON

Press the ON/OFF button to power on the control .

Press and hold the ON/OFF button for three (3)

seconds to power off the control .

UP AND DOWN ARROW BUTTONS

Used to increase or decrease the temperature set-point .

On units with optional timer installed the arrow buttons

are used to increase or decrease time, date, auto-start,

and auto-stop times .

TEMPERATURE RECALL BUTTON

Press the TEMPERATURE RECALL button to view

the actual cavity temperature . The display will show

the actual cavity temperature for fi ve (5) seconds

before reverting back to displaying the current

temperature set-point .

L.E.D. DIGITAL DISPLAY

The control has a four-digit L .E .D . display .

AUDIBLE BUTTON FUNCTION

The warmer’s audible button function can be turned ON or OFF .

1 . While the control is in OFF state, press and hold

the DOWN ARROW button for four (4) seconds .

2 . The display will show the current audible button

status, 0 (OFF) or 1(ON) . Press the UP or DOWN

arrows to toggle between the two states .

L.E.D. DISPLAY STATUS INDICATORS

OVERTEMP INDICATOR LIGHT

This indicator will illuminate and an alarm will sound

if the control senses a temperature of 71 °C (160°F)

or higher . The alarm can be muted by pressing the

ON/OFF button .

ERROR ACKNOWLEDGEMENT

To clear or acknowledge an error, press the

ON/OFF button . Press the ON/OFF button to

acknowledge the periodic alarm . If the alarm

continues or returns, the warmer is still experiencing

an error and may need service .

BUTTON LOCKOUT INDICATOR LIGHT

The lock indicator light will illuminate when the control

lock feature is engaged . Press the ON/OFF button

and UP ARROW simultaneously to lock the control .

Press the ON/OFF button and DOWN ARROW button

simultaneously to unlock the control .

POWER FAIL DETECTION

If the power fails for any reason while heating, the warmer

will retain its current operating state in memory . The control

will resume operating after the power is restored . In order to

alert the user that the power has failed, the decimal place on the

fi rst digit will fl ash. Press the ON/OFF button to acknowledge

the power failure and restoration .

NOTE:

If the timer option is installed, the warmer must be off

for more than 60 seconds to signal a power failure alarm . When

acknowledging a power interruption, the display will show the

length of time in hours and minutes that the control has been off

due to the power outage .

TEMPERATURE FORMAT SELECTION

While the control is in OFF state, press and hold

the TEMPERATURE RECALL button for four (4)

seconds to display the current temperature scale .

Press either the UP or DOWN arrows to toggle

between Fahrenheit and Celsius .

B L A N K E T C O N T R O L F E A T U R E S