PCB Load & Torque, Inc.

Toll-Free in USA 866-684-7107

716-684-0001

www.pcbloadtorque.com

GENERAL PURPOSE LOW PROFILE LOAD CELL OPERATION MANUAL

5

5.0 ELECTRICAL INSTALLATION

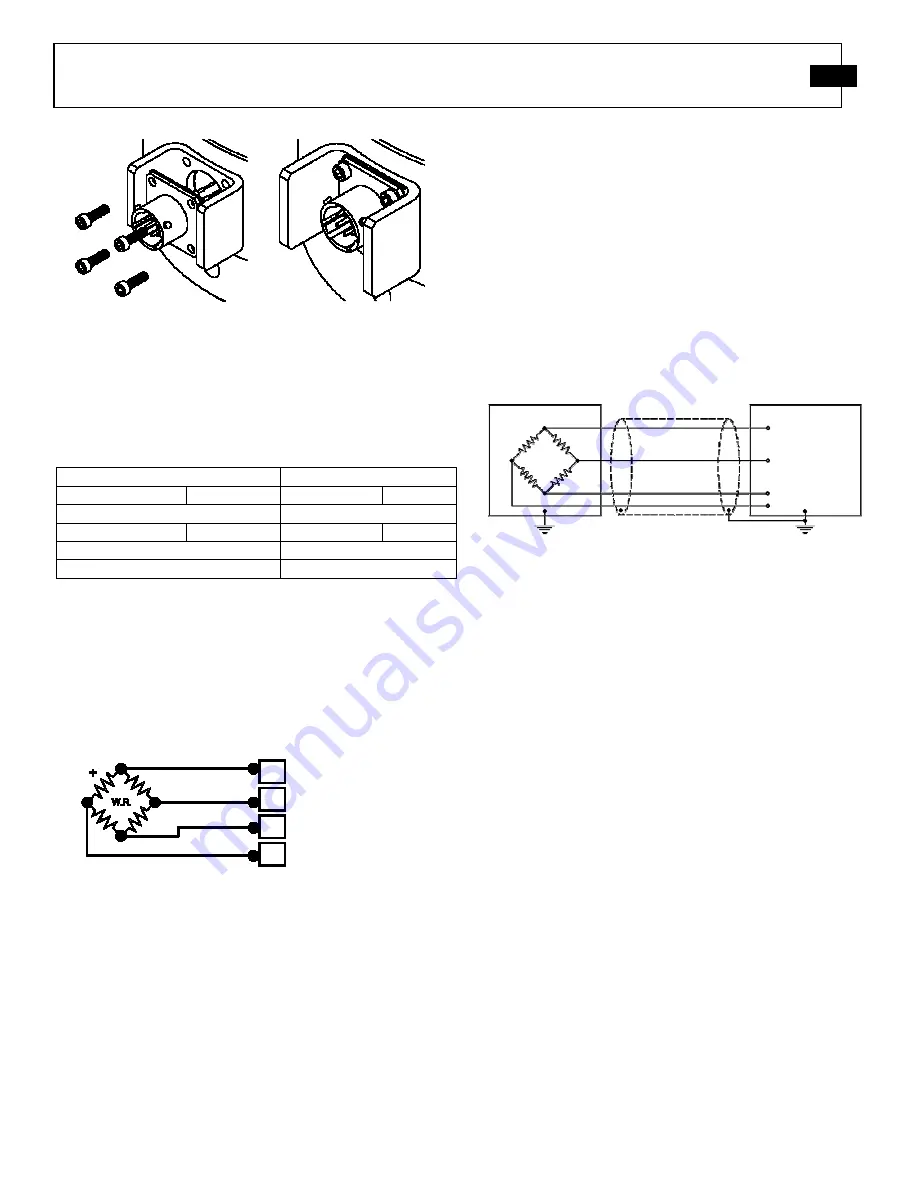

5.1 Electrical Drawing / Western Regional Std.

All load cells are wired following the Western Region

Standard. All models utilize strain gages configured into a

Wheatstone Bridge Circuit to produce the primary sensing

element. The four-arm Wheatstone bridge configuration is

shown below in Figure 11.

The gages are bonded to the load cell's structure.

Typically, a regulated DC or AC excitation is applied

between A and D of the bridge. When a force is applied to

the load cell, the Wheatstone bridge becomes unbalanced,

causing an output voltage between B and C, which is

proportional to the applied load. This configuration allows

for temperature and pressure compensation, as well as

cancellation of signals caused by forces not directly

applied to the axis of the applied load. Output is typically

expressed in units of mV/V of excitation.

5.2 Cable & Grounding Considerations

Proper grounding and shielding is required to prevent

electrical noise in strain gage load cell measuring systems.

The cable must be shielded twisted pairs with a drain wire.

Cable shields must be grounded only at one end, for example,

on the instrument or control system ground. The load cell

case is grounded by mechanical attachment to the structure to

which it is mounted.

The instrument or control system is grounded through its

power cord. Ground loops and measuring system wiring may

result in unstable or noisy signals.

A simple test with a voltmeter connected between the power

cord ground and the structure on which the load cell is

mounted can confirm that the structure has been properly

grounded. If the power cord ground and structure ground are

not at the same potential, it may be necessary to provide a

secure structure ground, perhaps by driving a copper rod and

attaching a ground strap.

6.0 CALIBRATION

Every general purpose low profile load cell purchased from

PCB Load & Torque, Inc. has been fully calibrated in tension

and compression per ISO/IEC 17025 procedures, and meets all

published specifications. Each load cell will come with a

calibration certificate designated with matching model and

serial numbers. PCB Load & Torque also offers calibration

services on an on-going basis.

6.1 Calibration Certificate Description

Calibration reports supplied with PCB Load & Torque general

purpose low profile load cells contain valuable information to

assist the customer in use of the equipment. A separate

calibration report is provided for tension and compression

calibrations

on

each

bridge.

Calibration

procedures,

equipment, and reports comply with ISO/IEC 17025.

Load Cell Receptacle “A”:

PT02E-10-6P

Mating Connector:

PT06A-10-6S

PCB Item No:

181-012A

Load Cell Receptacle “B”:

PC04E-10-6P

Mating Connector:

PC06A-10-6S

PCB Item No:

182-025A

Load Cell Receptacle “C”:

PT02E-12-8P

Load Cell Receptacle “D”:

PC01E-12-8P

Table 6

– Electrical Connection Options

Figure 12

- Grounding

Test Rig Ground

Power Supply

Instrument Ground

Cable Shielding

Load Cell

C

A

D

B

- Signal White

- Excitation Black

+ Excitation Red

+ Signal Green

Figure 11 - Western Regional Strain Gage Committee Wiring Code

Figure 9 - Attach the Connector

Protector (54823-02) using #4-40 x

3/8” Socket Head Cap Screws

Figure 10 - Fully Assembled