3.0 CONFIGURATION

This section describes the location and orientation of the Model

1092RC’s configuration switches and jumpers, and provides detailed

instructions for all possible settings.

3.1 CONFIGURING THE HARDWARE SWITCHES

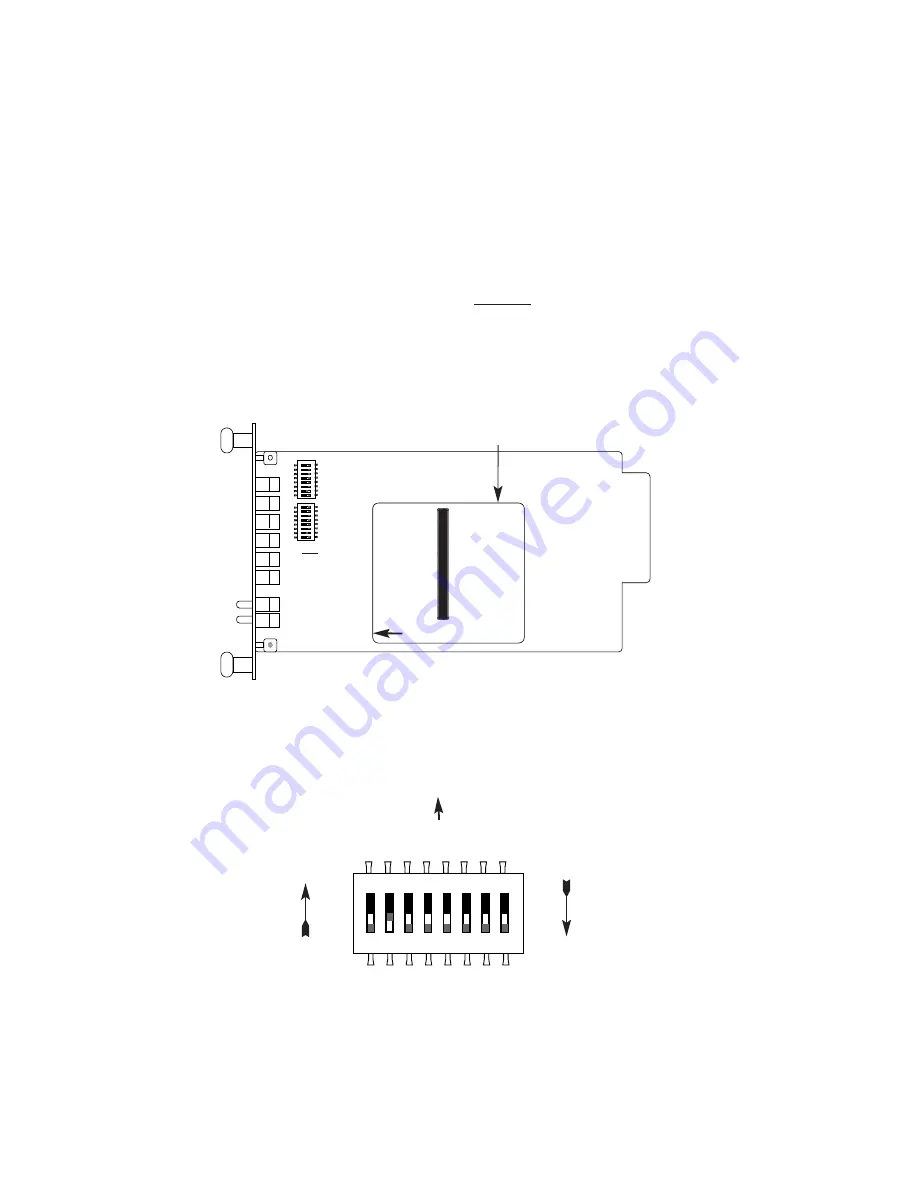

The Model 1092RC Series front card defaults to the use of

hardware switches for configuration. There is an interface driver board

strap, and two eight-position DIP switches, on the front card (see

Figure 1, below).

Figure 2 shows the orientation of the DIP switches with respect to

the “ON” and “OFF” positions.

5

ON

12345678

ON

12345678

Figure 1.

Model 1092RC, showing configuration switches and interface board

SW1

SW2

Interface

Driver

Board

THIS SIDE UP FOR V.35

FRONT

Figure 2.

Close up of configuration switches (both sets are identical in appearance)

NOTE:

The ON position is oriented toward the front of the Model 1092RC.

ON

1 2 3 4 5 6 7 8

OFF

ON

Front Panel

ON OFF

APPENDIX A

PATTON MODEL 1092RC SPECIFICATIONS

Transmission

Format:

Synchronous or asynchronous

Transmission Line:

Single unconditioned twisted pair

Clocking:

Internal, external or receive recover

Distance:

Up to 10.8 miles (17.3Km), all data rates, 19

AWG (.9mm)

Up to 7.2 miles (11.5Km), all data rates, 22

AWG (.6mm)

Up to 5 miles (8Km), all data rates, 24AWG

(.55mm)

Up to 3.41 miles (5.45Km), all data rates, 26

AWG(.4mm)

Data Rates:

Sync

32, 56, 64 & 128 kbps;

Async

0 - 38.4 kbps

Diagnostics:

V.52 compliant bit error rate pattern

(511/511E pattern) generator and detector

with error injection mode; Local Line

Loopback and Remote Digital Loopback,

activated by front panel switch or via serial

interface

LED Indicators:

TD, RD, CTS, CD, DTR, NS(no signal),

ER (error) and TM (test mode)

Connectors:

RJ-45 on line side; DB-25 female or M/34

female on serial interface side, depending

upon which interface rear card is installed.

Temperature:

32-140°F (0-60°C)

Altitude:

0-15,000 feet (0-4572 meters)

Humidity:

5 to 95% noncondensing

Dimensions:

Front Card: 4.81” x 3.10” x 0.95”

(12.2 x 7.8 x 2.4cm)

Rear Card: 3.33” x 2.8” x 0.95”

(8.4 x 7.1 x 2.4cm)

Weight:

Front Card: 0.22 lbs (.10Kg)

Rear Card (M/34 with V.35 interface): 0.16

lbs (.07Kg)

Rear Card (DB-25/RS-232 interface): 0.12

lbs. (.05Kg)

32

Summary of Contents for 1092RC

Page 3: ......

Page 5: ......

Page 7: ......

Page 9: ......

Page 11: ......

Page 13: ......

Page 15: ......

Page 17: ......

Page 19: ......

Page 21: ......

Page 23: ......

Page 25: ......

Page 27: ......

Page 29: ......

Page 31: ......

Page 33: ......

Page 35: ......

Page 37: ......

Page 39: ......

Page 40: ......