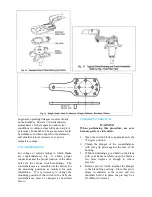

and adjusting nuts are shown in Fig. 1 and are

explained in step 3.

Step 2—Assemble Insulators

Assemble the insulator stacks to the switch base.

Do not disturb the position of the switch crank

when mounting the insulator stack to the rotor

bearing, as the crank has been properly located

at the factory. In some cases, involving higher

voltage switches, the installer may choose to

mount the switch bases on the structure before

assembling the insulators. In such cases the

switch bases should be mounted on the

supporting structure in the positions shown on

the installation drawing. The bases should be

level and parallel to each other. Make sure that

the base for the drive phase is in the correct

location and operating cranks are at their proper

angles.

Step 3—Insulator Stack Alignment

Lower voltage switches 8.25 thru 72.5kV

generally do not require insulator stack

alignment. Where required, the insulator stacks

of switches thru 242kV can be aligned using

open-end shims or leveling screws and/or

adjusting nuts (Fig. 1) if supplied (optional).

•

If using shims, place the shims under the

insulator supports (rotor bearing or spacer

mounting flange) where the bolts secure the

rotor bearing or spacer mounting flange to

the switch bases.

•

If optional leveling screws and/or adjusting

nuts have been supplied, as shown in Fig. 1,

adjust the leveling screw and/or adjusting

nut to align the insulator stacks. Loosen all

hardware before jacking to prevent binding.

Step 4—Mount Current Carrying Parts

Caution:

When uncrating switches having blade

counter balances (Fig. 3), be careful to keep

linkage on dead center until the blade and hinge

assembly have been bolted in place on the

insulator columns. Otherwise, the

counterbalance springs may collapse the hinge

end toggle, possible causing injury to workmen.

Make certain that the base crank is in the proper

position when mounting current carrying parts,

i.e. base crank rotated to the maximum counter

clockwise position with the blade closed. Care

should be exercised when hoisting the blade

hinge and jaw assemblies into position to

prevent scratches or damage to these current-

carrying parts. When assembling the jaws on the

insulator columns, leave the mounting bolts

finger tight. This will permit the jaw base to be

rotated and shifted slightly for subsequent

3 |

P a g e

Summary of Contents for TTR6

Page 1: ...IB TTR6 B May 2012 ...

Page 6: ...5 P a g e ...