Materials Testing Machine

Operation

8

012-13762C

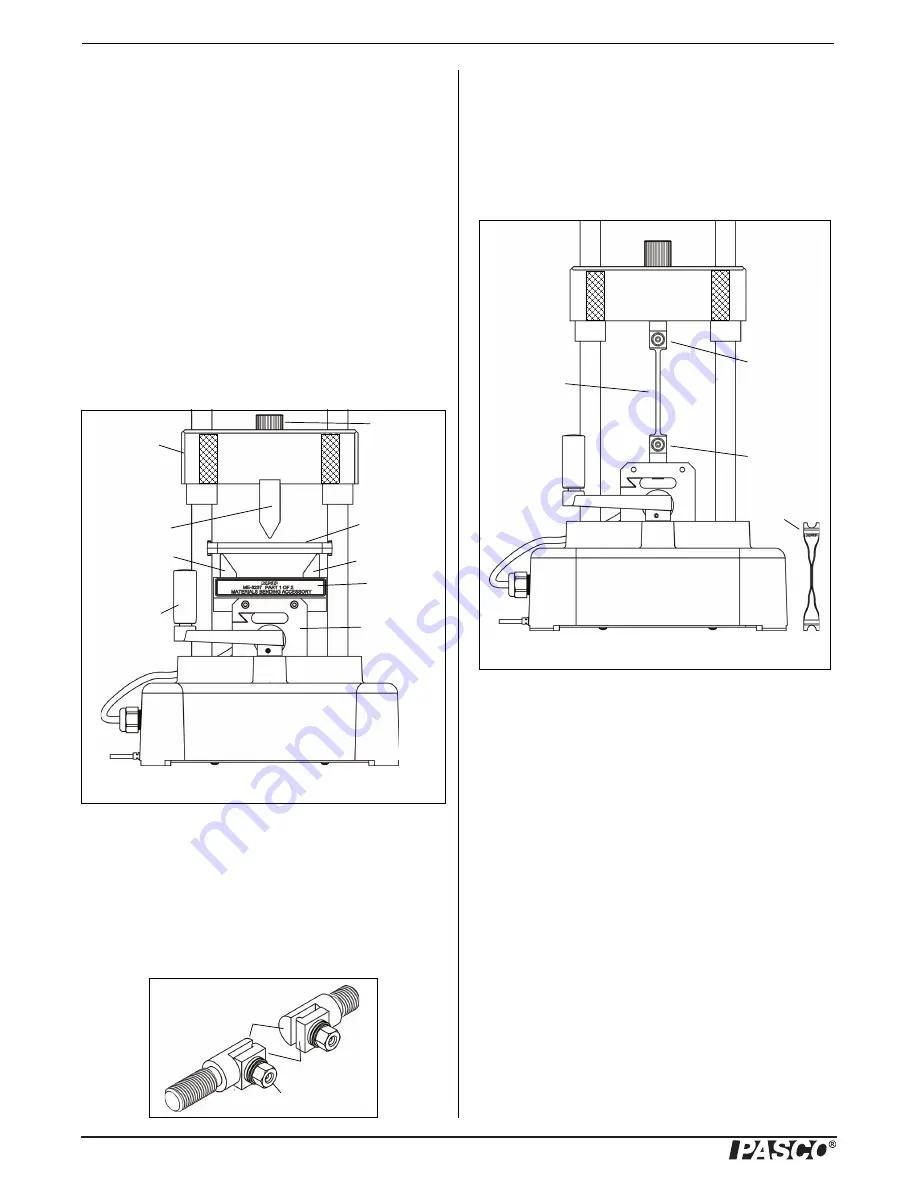

Use the sample nut to secure the plunger in place on the load

bar. Remove the screws from the base for the anvils and

align the base on top of the load cell. Use the screws and the

hex key to fasten the base in place.

Place a sample for testing on the two support anvils.

Attach the Safety Shields

Attach the Velcro® hook material on the two safety shields

to the Velcro® loop material on the front and back of the

Load Bar. Adjust the position of the shields so that they will

block any fragments that may come from the sample.

Apply a Force

Turn the crank counterclockwise to apply a compression

force through the plunger onto the sample. (Note that the

default in the software shows the force and position as ‘posi-

tive’ when a compression force is applied.)

Materials Coupon Adapter (ME-8238)

The Materials Coupon Adapter includes two coupon clamps,

a “tee-handle”, and a 3/8” socket (12 point). One clamp fits

in the load cell and the other fits in the load bar. They can be

used to mount a plastic coupon (AP-8222) or metal coupon

(AP-8223) onto the Materials Testing System for testing of

tensile strength.

Loosen but do not remove the hex nut on each clamp. The

jaws of the clamp are spring loaded, so the moveable jaw

will separate from the fixed jaw. Screw the clamp with the

shorter threaded section into the load cell. Put the threaded

section of the other clamp up through the hole in the load

bar, and use the sample nut to hold the upper clamp. NOTE:

Do not completely tighten the sample nut yet.

Carefully place one end of a coupon between the jaws of the

bottom clamp. While holding the moveable jaw to keep it

aligned with the fixed jaw, use the tee-handle and socket to

tighten the hex nut. CAUTION: Each coupon is fragile. Do

not let the moveable jaw twist out of alignment with the

fixed jaw as this might bend the coupon.

Turn the upper clamp so that it is aligned with the lower

clamp. Adjust the position of the load bar so that you have

room to carefully put the other end of the coupon between

the jaws of the upper clamp. Keep the movable jaw aligned

with the fixed jaw so that the coupon does not twist or bend.

Once again, tighten the hex nut.

Hold the upper clamp so it remains parallel to the lower

clamp and tighten the sample nut slightly to remove any

slack in the coupon.

Attach the Safety Shields

Attach the Velcro® hook material on the two safety shields

to the Velcro® loop material on the front and back of the

Load Bar. Adjust the position of the shields so that they will

block any fragments that may come from the sample.

Turn the crank clockwise to apply a tension force to the cou-

pon.

Figure: Materials Bending Accessory

Load

Cell

Plunger

Sample

Anvil

Anvil

Crank

Handle

Sample

Nut

Base

Load Bar

(crosshead)

Movable

Jaw

Fixed

Jaw

Hex Nut

Upper

Clamp

Lower

Clamp

Metal

Coupon

Plastic

Coupon

Figure: Materials Coupon Adapter