www.parweld.co.uk

www.parweld.co.uk

9

2. Position wire over joint. The end of the wire may be lightly

touching the work.

3. Lower welding helmet, operate torch trigger, and begin welding.

Hold the torch so the contact tip to work distance is about 3/8”

(10 mm).

4. To stop welding, release the torch trigger and then pull the torch

away from the work after the arc goes out.

5. When no more welding is to be done, close valve on gas

cylinder (if used), momentarily operate torch trigger to release

gas pressure and turn off the machine.

6.1.2 Optimising Weld Parameters (Manual)

NOTE These settings are guidelines only. Material and wire

type, joint design, fit up, position, shielding gas, etc. affect

settings. Produce test welds to be sure they comply to

specifications.

Material thickness determines weld parameters.

1. Convert Material Thickness to Amperage (A) (0.25mm = 1 Amp)

3.2mm = 125 A

2. Select Wire Size

Amperage Range

Wire Size

40 - 145 A

0.8 mm

50 - 180 A

1.0 mm

3. Select Wire Speed (Amperage)

Wire Size

Feed speed

0.8 mm

0.05m/min per Amp

1.0 mm

0.04m/min per Amp

So based on 3.2 mm material thickness amperage should be 125A if

using 1.0mm wire then the wire feed speed should be

0.04 X 125= 5m/min

Wire speed (amperage) controls weld penetration

4.Select Voltage. Voltage controls height and width of weld bead.

Low Voltage: wire stubs into work

High Voltage: arc is unstable (spatter)

Set voltage midway between high/low, then fine tune accordingly.

6.1.3 Optimising Weld Parameters (Synergic)

In synergic mode you may wish to trim the voltage (4) to optimize

the welding process, you can rotate the voltage control left or right to

decrease or increase the preset welding voltage. You can also adjust

the inductance (11) to change the hardness of the arc.

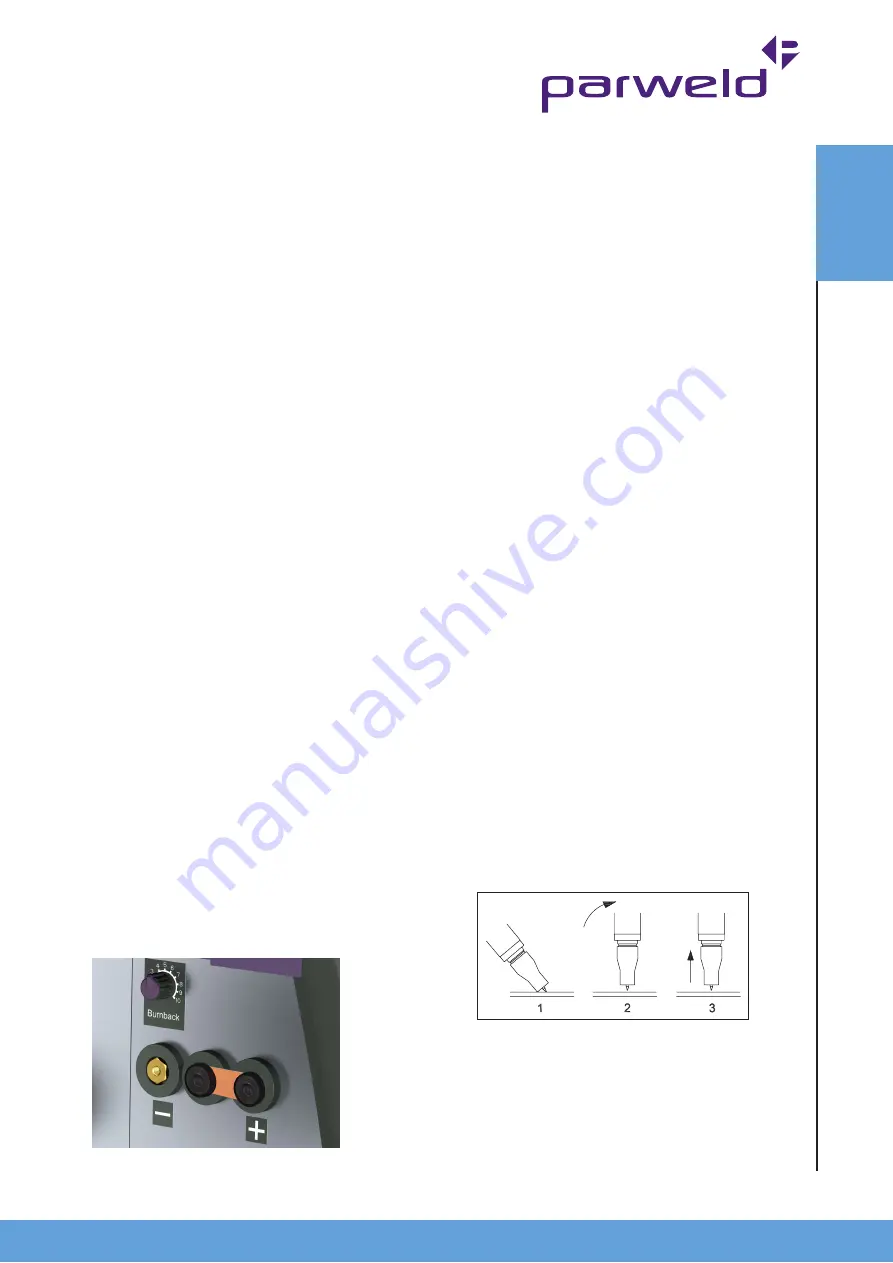

6.1.4 Burn Back

The amount of wire stick out at the end of the torch after welding

can be adjusted by using the burn back control inside the spool

cover shown in Figure 3. Increasing burn back will reduce the

amount of wire projecting from the torch at the end of a weld.

Fig.3

6.2 MMA welding

6.2.1 Torch installation

MMA cable connections

Connect work return lead to negative terminal.

6.2.2 Work return lead connection

MMA cable connections

Connect work return lead to negative terminal.

6.2.3 Operation

Select the operating mode on the front panel to MMA (11)

Using the optional electrode holes clamp a welding electrode in the

holder and adjust the welding amperage on the front panel so that

it is approximately 40A per mm diameter of electrode e.g. 3.2mm

electrode requires 3.2x 40A= 128A . Strike the arc by stroking the

electrode on the workpiece. And lift away when you wish to break

the arc.

6.3 TIG Welding Operation

To begin TIG welding operation:

NB: this machine is only operates in DC Lift TIG mode and therefore

NOT suitable for TIG welding aluminium.

1. Unthread the MIG welding wire from the MIG Torch and remove

the spool or secure the wire to prevent unspooling.

2. Remove the MIG Welding Torch from the Euro Connection (8).

3. Attach the specially adapted optional TIG Torch (Stock Code

PRO17-12S1MPG

) to the Euro Connection (8).

4. Connect the Work Return Lead to the + Outlet (9).

5. Connect the Machine via the Gas Hose & Regulator to a suitable

gas source (for TIG operation this will be Pure Argon and may differ

to what was being used for the MIG process)

6. Adjust the Polarity Bridge shown in Figure 3 so that it is connected

to the – pole

7. Use the function selection control (11) to select the TIG function

8. Adjust the Amperage control (3) to the desired power output (as a

guide only 1.0mm material thickness = 30amps of welding Current)

9. Adjust the Down Slope control (4) 2-3 seconds should be sufficient

10. Adjust the 2T, 4T (7) control this operates the trigger action

11. You are now ready to begin. Lightly touch the Tungsten Electrode

to the work piece press the trigger switch and draw the torch away

extending the arc to around 3-5mm (The gas will be automatically

activated and stopped with the trigger action).

In 2T mode keep the trigger switch depressed, the arc will stabilise

allowing the welding process to proceed to finish welding release the

trigger, the arc will stop decreasing power over the Down Slope time

set earlier.

In 4T mode after the initial soft arc has been drawn out release

the trigger, the arc will increase power to the welding amperage

set earlier. This allows for continuous welding without the need the

keep the trigger depressed. To stop welding, depress the trigger this

activates the Down Slope function, releasing the trigger will stop the

operation.

OPERA

TION