www.parweld.co.uk

12

POWER SOURCE PROBLEMS

Description

Possible cause

Remedy

A total loss of

power, pilot

lamp is off,

no output,

the fan is not

operating

(a) Failure of input

voltage

(b) Possible over voltage

(c) Internal fault with the

machine

(a) Re-establish

mains supply

(b) Check voltage

and if necessary

move machine to

alternative supply

(c) Have a qualified

service engineer

inspect then repair

the welder

Fault lamp is

on, no power

output

(a) Machine overheated

(b) Over current state

(c) Internal fault with

machine

(a) Allow to cool

with fan running

(b) Switch off

mains power to the

machine and re start

(c) Have a qualified

service engineer

inspect

then repair the

welder

ROUTINE MAINTENANCE

The only routine maintenance required for the power supply is a

thorough cleaning and inspection, with the frequency depending on

the usage and the operating environment.

Warning

Disconnect primary power at the source before removing the cover.

Wait at least two minutes before opening the cover to allow the

primary capacitors to discharge.

To clean the unit, remove the screws securing the outer cover,

lift off the outer cover and use a vacuum cleaner to remove any

accumulated dirt and dust. The unit should also be wiped clean,

if necessary; with solvents that are recommended for cleaning

electrical apparatus.

8.0 Accessories

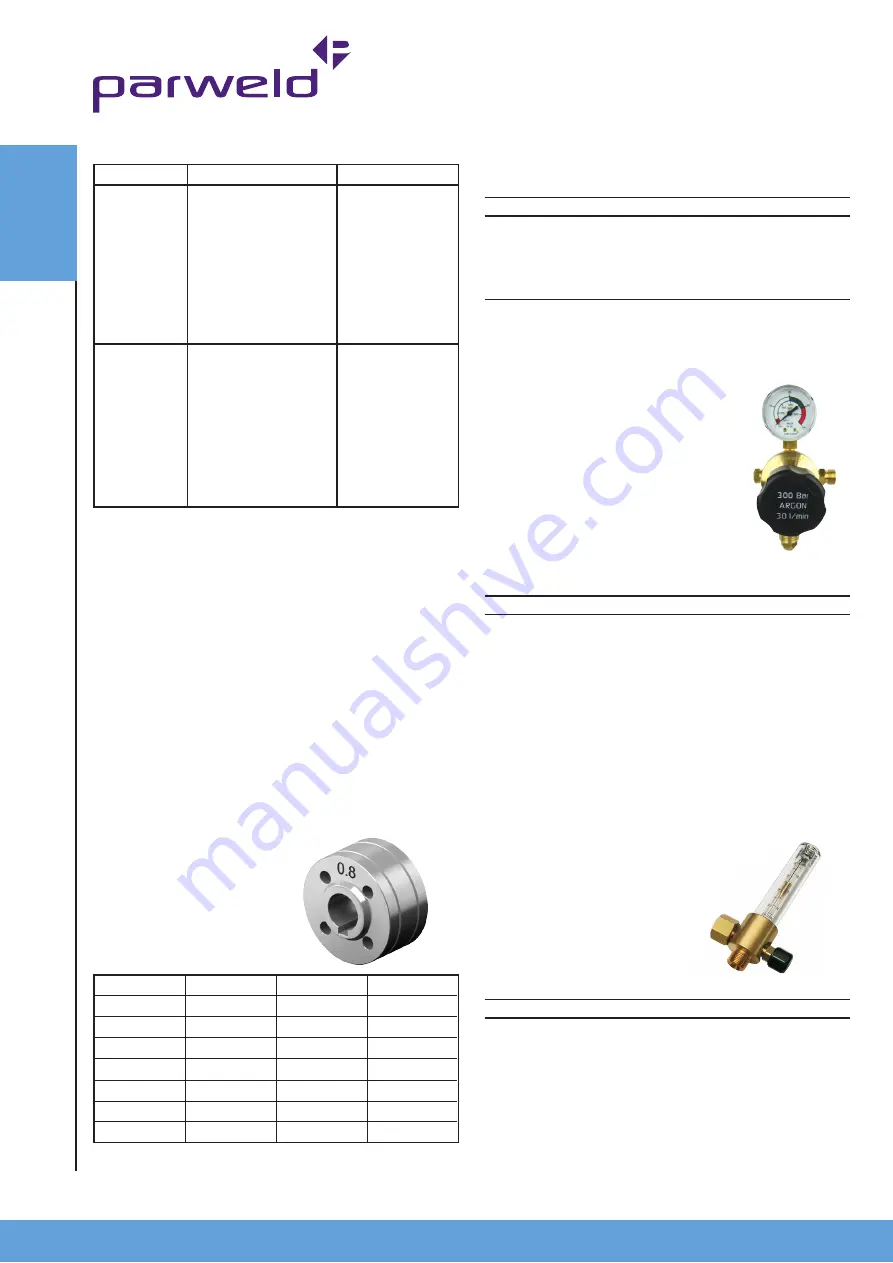

8.1 Feed Rolls

Part No.

Groove

Wire Sizes

Wires

DR2V0608

Plain V

0.6 - 0.8

Fe, Ss

DR2V0609

Plain V

0.6 - 0.9

Fe, Ss

DR2V1012

Plain V

1.0 - 1.2

Fe, Ss

DR2K0809

Knurled V

0.8 - 0.9

FC

DR2K1012

Knurled V

1.0 - 1.2

FC

DR2U0809

Plain U

0.8 - 0.9

Al

DR2U1012

Plain U

1.0 - 1.2

Al

8.2 Torch Spares

Stock Code

Description

CKE403

Electrode Holder with 3m Lead

CKC403

Earth Lead 3m with Clamp

PRO17-12S1MPG

Pro-Grip TIG Torch

WP17AK

Tig Spares Kit in Plastic Case

8.3 Gas Equipment

Everyday Gas Regulators – 300 BAR

Single Stage

Features

Flow rate up to 96m

3

/h (3389 ft

3

/h)

• Full 300 bar capability

• Outlet pressure indicated on the bonnet

• Bottom entry design suited for top outlet

cylinder valves

Fittings

• Fitted with standard

3

/

8

” BSP outlet

• Fitted with

5

/

8

” BSP inlet connections

Stock Code Description

Maximum Outlet Pressure

E700140

Argon Preset Regulator

3.0 Bar

E700141

Argon Indicator Regulator

3.0 Bar

E700113

1 Gauge Argon

30 lpm flow

E700123

2 Gauge Argon

30 lpm flow

8.4 Flow Meters

Features

• Designed from brass bar whilst the tube and cover are moulded

from high quality polycarbonate to ensure high impact resistance

and clarity

• Calibrated to operate at an inlet pressure

of 30PSI

• Sensitive needle valve provides easy adjustment

and the downward facing outlet connection

eliminates hose kinking.

Fittings

• Fitted with standard

3

/

8

" BSP inlet and

outlet connections

Stock Code

Description

706100

Flow Meter Mixed Gas 15 lpm

ACCESSORIES