34

35

HEDGE TRIMMER GEARBOX LUBRICATION

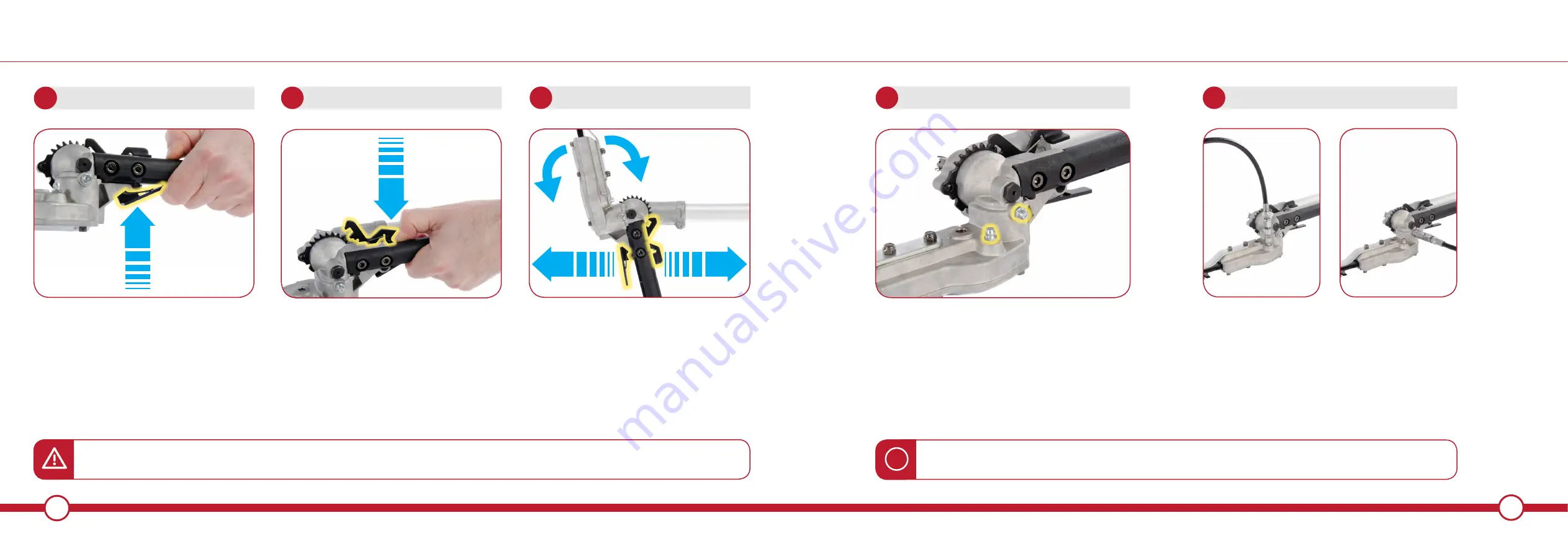

ADJUSTING HEDGE TRIMMER ANGLE

With the engine stopped, grip the

adjustment handle

Lift the angle adjustment locking lever with

your index finger and hold

1

LOCKING LEVER

1

2

ANGLE ADJUSTMENT LEVER

Whilst still holding the angle adjustment

locking lever, press down with your thumb

on the angle adjustment lever and adjust

the cutting head to a suitable angle.

WARNING!

The Hedge Trimmer adjustment handle contains moving parts which could cause injury if used incorrectly.

NOTE:

Always wear safety gloves when operating moving parts to help prevent the risk of injury.

Once the cutting head is adjusted to the

required angle, release the levers to lock

the cutting head into position.

2

ADJUSTMENT & LOCK

The components within the Hedge Trimmer

gearbox have to work very hard and as a result

MUST remain well lubricated at all times. Before or

after each use.

There are two grease nipples on the Hedge

Trimmer gearbox housing. Be sure to add grease

to both.

Connect a compatible grease gun to the gearbox

assembly's grease nipples.

Pump gearbox grease into the grease nipples.

Use a general purpose gearbox grease.

1

HEDGE TRIMMER GREASE NIPPLES

2

ADD GREASE TO HEDGE TRIMMER

WARNING!

Use an appropriate gearbox grease. Failure to do so can result in unit failure.

NOTE:

Always keep gearbox lubricated either before or after use. Lack of lubrication can cause unit failure

i