27

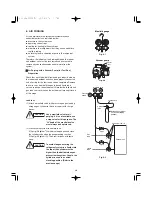

Caution Before Connecting Tubes Tightly

(1) Apply a sealing cap or water-proof tape to prevent dust or

water from entering the tubes before they are used.

(2) Be sure to apply refrigerant lubricant to the matching

surfaces of the flare and union before connecting them

together. This is effective for reducing gas leaks. (Fig. 5-4)

(3) For proper connection, align the union tube and flare tube

straight with each other, then screw in the flare nut lightly

at first to obtain a smooth match. (Fig. 5-5)

●

Adjust the shape of the liquid tube using a tube bender at

the installation site and connect it to the liquid tubing side

valve using a flare.

Cautions During Brazing

●

Replace air inside the tube with nitrogen gas to

prevent copper oxide film from forming during the

brazing process. (Oxygen, carbon dioxide and Freon

are not acceptable.)

●

Do not allow the tubing to get too hot during brazing.

The nitrogen gas inside the tubing may overheat,

causing refrigerant system valves to become dam-

aged. Therefore allow the tubing to cool when brazing.

●

Use a reducing valve for the nitrogen cylinder.

●

Do not use agents intended to prevent the formation

of oxide film. These agents adversely affect the

refrigerant and refrigerant oil, and may cause damage

or malfunctions.

5-2. Connecting Tubing Between Indoor and Outdoor

Units

(1) Tightly connect the indoor-side refrigerant tubing extended

from the wall with the outdoor-side tubing.

(2) To fasten the flare nuts, apply specified torque as at right:

●

When removing the flare nuts from the tubing connections,

or when tightening them after connecting the tubing, be

sure to use 2 adjustable wrenches or spanners as shown.

(Fig. 5-6)

If the flare nuts are over-tightened, the flare may be dam-

aged, which could result refrigerant leakage and cause in

injury or asphyxiation to room occupants.

●

For the flare nuts at tubing connections, be sure to use the

flare nuts that were supplied with the unit, or else flare nuts

for R410A (type 2). The refrigerant tubing that is used must

be of the correct wall thickness as shown in the table at

right.

Apply refriger

a

nt

l

ub

ric

a

nt

Fig. 5-4

Flare nut

Union

Fig. 5-5

Fig. 5-6

Indoor unit

Outdoor unit

Spanner

Torque wrench

Tube diameter

ø1/4"

(ø6.

3

5 mm)

ø

3

/8"

(ø9.52 mm)

ø1/2"

(ø12.7 mm)

ø5/8"

(ø15.88 mm)

ø

3

/4"

(ø19.05 mm)

Ti

g

htenin

g

torque,

approximate

120 – 160 l

bs

·

in.

(140 – 180 kgf

·

cm)

3

00 –

3

60 l

bs

·

in.

(

3

40 – 420 kgf

·

cm)

4

3

0 – 480 l

bs

·

in.

(490 – 550 kgf

·

cm)

590 – 710 l

bs

·

in.

(680 – 820 kgf

·

cm)

870 – 1040 l

bs

·

in.

(1000 – 1200 kgf

·

cm)

1/

3

2"

(0.8 mm)

1/

3

2"

(0.8 mm)

1/

3

2"

(0.8 mm)

5/128"

(1.0 mm)

over 5/128"

(1.0 mm)

Tube thickne

ss

Because the pressure is approximately 1.6 times

higher than conventional refrigerant pressure, the

use of ordinary flare nuts (type 1) or thin-walled

tubes may result in tube rupture, injury, or

asphyxiation caused by refrigerant leakage.

●

In order to prevent damage to the flare caused by

over-tightening of the flare nuts, use the table

above as a guide when tightening.

●

When tightening the flare nut on the liquid tube,

use an adjustable wrench with a nominal handle

length of 7-7/

8

".

Summary of Contents for U-36LE1U6

Page 35: ...35 7 3 Outdoor Unit PCB Setting CN51 CN50 D043 LED2 D042 LED1 S003 CN33 S002 S004 Fig 7 4...

Page 46: ...46...

Page 47: ...47...

Page 48: ...DC0811 0 Printed in Japan...