1 Safety Precautions

1.1. General Guidelines

1. When conducting repairs and servicing, do not attempt to modify the equipment, its parts or its materials.

2. When wiring units (with cables, flexible cables or lead wires) are supplied as repair parts and only one wire or some of the wires

have been broken or disconnected, do not attempt to repair or re-wire the units. Replace the entire wiring unit instead.

3. When conducting repairs and servicing, do not twist the Faston connectors but plug them straight in or unplug them straight out.

4. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

5. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

6. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1M

W

and 5.2M

W

.

When the exposed metal does not have a return path to the chassis, the reading must be

.

Figure 1

1.1.2. Leakage Current Hot Check (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5k

W

, 10 watts resistor, in parallel with a 0.15µF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliamp. In case a measurement is outside of the limits

specified, there is a possibility of a shock hazard, and the equipment should be repaired and rechecked before it is returned to

the customer.

2

TY-FB10HMD / TY-FB10HMDC

Summary of Contents for TY-FB10HMD - Monitor Terminal Expansion Board

Page 5: ...4 Replacement 5 TY FB10HMD TY FB10HMDC ...

Page 6: ...5 Connection 6 TY FB10HMD TY FB10HMDC ...

Page 9: ...7 1 Schematic Diagram Notes 7 Block and Schematic Diagram TY FB10HMD TY FB10HMDC 9 ...

Page 16: ...TY FB10HMD TY FB10HMDC 16 ...

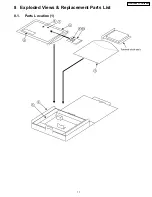

Page 17: ...8 Exploded Views Replacement Parts List 8 1 Parts Location 1 17 TY FB10HMD TY FB10HMDC ...

Page 18: ...8 2 Parts Location 2 18 TY FB10HMD TY FB10HMDC ...

Page 19: ...8 3 Replacement Parts List Notes 19 TY FB10HMD TY FB10HMDC ...