7

3 Service Navigation

3.1.

Introduction

This service manual contains technical information, which allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, the information will be followed by service manual to be controlled with original service manual.

3.2.

General Description About Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30

°

C (86

°

F) more than that of the

normal solder.

Distinction of P.C.B. Lead Free Solder being used

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the P.C.B. using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the P.C.B. cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30

°

C

(662±86

°

F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01KS-----------(0.3mm 100g Reel)

RFKZ06D01KS-----------(0.6mm 100g Reel)

RFKZ10D01KS-----------(1.0mm 100g Reel)

Note

* Ingredient: tin (Sn) 96.5%, silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

Summary of Contents for HC-V750EB

Page 12: ...12 ...

Page 13: ...13 ...

Page 14: ...14 ...

Page 15: ...15 ...

Page 16: ...16 ...

Page 18: ...18 ...

Page 19: ...19 ...

Page 20: ...20 ...

Page 21: ...21 ...

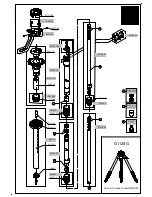

Page 31: ...31 8 2 PCB Location ...

Page 34: ...34 8 3 1 Removal of the Side Case L Unit Fig D1 Fig D2 ...

Page 35: ...35 Fig D3 8 3 2 Removal of the Top Case Top Operation Fig D4 ...

Page 36: ...36 Fig D5 Fig D6 ...

Page 37: ...37 8 3 3 Removal of the Front Case Unit Fig D7 Fig D8 ...

Page 39: ...39 Fig D12 Fig D13 ...

Page 41: ...41 Fig D16 Fig D17 8 3 9 HC W850M V750M only Removal of the ESD P C B Unit Fig D18 ...

Page 42: ...42 8 3 10 Removal of the BR Frame Unit Speaker LCD Unit Fig D19 Fig D20 ...

Page 44: ...44 Fig D24 8 3 13 HC V750 V757 V750M V730 Removal of the LCD Hinge Unit Fig D25 ...

Page 45: ...45 Fig D26 8 3 14 Removal of the Monitor P C B LGP Unit LCD Fig D27 ...

Page 46: ...46 Fig D28 8 3 15 Removal of the Mic P C B Fig D29 ...

Page 47: ...47 8 3 16 Removal of the Front Base Barrier R Barrier F Photo Light P C B Fig D30 Fig D31 ...

Page 49: ...49 Fig D34 8 3 19 Removal of the Kurupon Unit Front P C B Fig D35 ...

Page 54: ...54 Level Shot Adjutment Chart ...

Page 56: ...56 9 1 2 Adjustment Items Adjustment item as follows ...

Page 59: ...59 ...

Page 60: ...60 ...

Page 61: ...61 ...

Page 62: ...62 ...

Page 63: ...63 ...

Page 64: ...64 ...

Page 65: ...65 ...