Operation manual for Narrow-pitch connectors F4S

Panasonic Corporation

industrial.panasonic.com/ac/e/

©

Panasonic Corporation 2017

ACCTF5E-5 201704

- 7 -

(4)

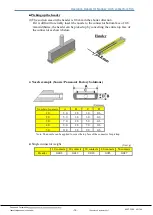

Precautions when providing a pattern and through-hole inside the prohibited

area

As shown below, the header’s post extends down to the bottomface of the molded

part, and the post extends horizontally beyond the molded part becomes the

terminal.

From this structure,pay attention to the following points.

①

When providing an uninsulated through-hole, make sure to design it so that it

does not interfere with adjacent terminals.

②

It is recommended that the patterns not be interfered in contiguous contacts.

(5)

Precautions when providing an insulated through-hole in a prohibited area

As shown below, the header’s post extends down to the bottomface of the molded

part, and the post extends horizontally beyond the molded part becomes the

terminal.

If an insulated through-hole is placed in the prohibited area, the gap between the

pattern and connector terminal becomes wider, which may result in poor soldering.

①

interfering with

adjacent terminal

②

interfering with

adjacent terminal

Lead out straight to avoid

interference with adjacent terminals

Sectional view

A gap becomes

wider and increases

the risk of poor

soldering.

●

Key point.

We recommend that you provide a through-hole closer to the center, out of the prohibited area.

A 50-µm step

between the terminal

and molded part

A gap can be

absorbed by a step

between the molded

part and the

terminal.

Sectional view

Top view

Through-hole

prohibited area

●

Key point

When leading out a pattern

that is not insulated inside,

be

careful not to contact any

adjacent terminals.

●

If there is a through-hole in the prohibited area

post

terminal