Operation manual for Narrow-pitch connectors F4S

Panasonic Corporation

industrial.panasonic.com/ac/e/

©

Panasonic Corporation 2017

ACCTF5E-5 201704

- 21 -

04. Precautions for mating and unmating

04-1. Precautions for mating

This connector features a compact and thin design. Although it is designed to be

easily handled, follow the rules for mating below to avoid damage to the molded part

and buckling or deformation of the contact.

(1)Roughly position the connector on the FPC board to a mating position of the

connector on the motherboard.

If the reference mark described on Page 5 is

provided, tentative positioning becomes easy.

(2)Slightly move the connector on the FPC board in the X and Y directions to check

that the mating position is correct.

(3)Lightly press the connector until mating between the simple locking sections and

mating between the contacts and posts of both connectors are completed.

A snapping sound will indicate that the simple locking sections are completely

mated.

(4)After completing the mating process, check that the clearance between the FPC

board and the motherboard is visibly even in both the X and Y directions.

If the space is not even, mating may not be completed. Unmate the connectors

once, check that there is no damage, and press them in again.

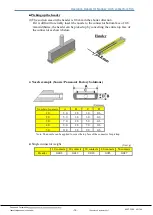

The following ways of mating in the drawings may cause deformation of the contacts,

crushing of the molded part, generation of resin particles that cause a contact failure

when entering the contact section, a return failure of the socket contact due to

crushed molded part, etc. Make sure to avoid mating in the following ways.

Press-fitting while the mating inlets of

the socket and header are not matched.

Strongly pressed and twisted

Tilted mating