Operation manual for Narrow-pitch connectors F4S

Panasonic Corporation

industrial.panasonic.com/ac/e/

©

Panasonic Corporation 2017

ACCTF5E-5 201704

- 12 -

4)

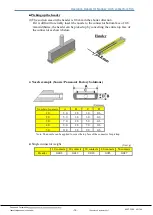

Metal Mask Design

Since this connector is designed with an ultra low-profile, pay attention to the

following precautions for reflow soldering.

(1)In addition to the amount of applied solder, the reflow-soldering environment and

temperature profile affect the finish quality after reflow soldering. Make sure to

adjust the amount of solder applied after checking the finish quality in a test run.

(2)Compared with natural air reflow soldering, N2 reflow soldering can reduce

oxidization of the melted solder surface. This significantly improves the solder

wettability. Therefore, make sure to apply an appropriate amount of solder.

(3)

Do not apply

an excessive amount of solder

,

otherwise, solder or flux may creep

near the contact section and reduce contact reliability or cause interference during

mating. Pay careful attention.

(4)It is recommended that solder with a grain diameter of 40

μ

m or smaller is used

so as to print a constant amount of solder.

(5)Check the latest specifications for the metal mask pattern.

Refer to the following pages for the current related dimensions.