Operation manual for Narrow-pitch connectors F4S

Panasonic Corporation

industrial.panasonic.com/ac/e/

©

Panasonic Corporation 2017

ACCTF5E-5 201704

- 10 -

(2)

FPC board specifications

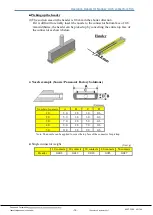

Control the thicknesses of the coverlay and adhesive to prevent poor

soldering.

There is a clearance of about 0.05 mm between the bottom surface of the

terminal and the molded part.

Therefore, minimize the thickness of the coverlay, etc. so as to prevent the

occurrence of poor soldering.

If poor soldering occurs frequently, check the actual thickness of each insulation

layer.

Generally, the coverlay thickness is set to about 30 μm, including the

adhesive. If the thickness exceeds 30 μm, design the board so as to remove the

coverlay under the connector.

(3)This connector is often used for connecting the motherboard and FPC board. In

this case, if the FPC board is too short, a load that causes deviation will be applied

to the connector.

Make sure to create a design that provides some allowance in the FPC board.

Connector

terminal

Molded part of the connector

Coverlay (polyimide)

Adhesive (epoxy adhesive recommended)

Adhesive (epoxy adhesive recommended)

Copper foil

Base material (polyimide)

Reinforcing plate + Adhesive

(epoxy adhesive recommended)

X Too long

Fixed

Connector

X Too short

Positional deviation

Motherboard

Part where FPC board is

fixed