•

Protect the amplifier from heat radiation or hot air.

•

With the 350

C

662 °F

heat-resistant type fiber, the

surface of the fiber head or the spiral may be discolored

by heat. However, this does not affect its performance.

102

FX-301

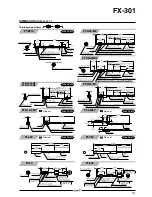

Connection with reflective coaxial type fiber

•

With reflective coaxial type fiber, insert the center fiber

cable (single-core) into the beam-emitting inlet and the

outer fiber cable (multi-core) into the beam-receiving inlet.

FD-H35-M2

or

FD-H20-M1

is marked ‘P’ on the beam-

emitting fiber cable and ‘D’ on the beam-receiving fiber cable.

FD-WG4

,

FD-WSG4

and

FD-G4

,

FD-G6

,

FD-G6X

are

composed of beam-emitting and beam-receiving fiber

cables that are different in diameter.

FD-G500

,

FD-EG1

,

FD-EG2

,

FD-EG3

,

FD-E22

,

FD-H20-21

and

FD-ENM1S1

are marked P on the

beam-emitting fiber cable.

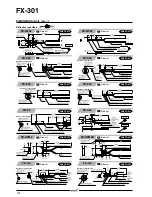

Fiber cable bending radius

•

If the fiber cable is bent at a smaller bending radius than allowable

bending radius, the sensing range decreases due to beam attenuation.

Fiber

Note: Please note that the 350 °C

662 °F

heat-resistant fibers, vacuum-

resistant and chemical-resistant

fibers cannot bend less than the

allowable bending radius.

Notes: 1) In case the fiber cables are not inserted to a position where they

stop, the sensing range reduces.

Notes:

2) Before connecting fiber cables to the amplifier, mount the fiber

attachments on their ends.

PRECAUTIONS FOR PROPER USE

.

•

Take care that, since the aperture angle of this product is very

narrow, the beam may not be received depending upon the setting.

At the time of installation, determine a reference plane, as shown in

the figure below, and taking sufficient care against beam

misalignment or tilt, install the emitting and receiving fibers so that

they are parallel.

<

FT-K8

>

Narrow beam type fiber mounting

•

Install the fiber using M3

countersunk head screws.

The tightening torque should

be 0.3 N

m or less.

Further, when using the fiber

at places having intense

vibrations, use a screw-

locking adhesive, etc.

•

If mineral oil or solvent containing mineral oil component

adheres to the sensing surface, the lens may be

deformed. Take sufficient care to handle them.

•

Take care that, since the aperture angle of this product is

very narrow, the beam may not be received depending

upon the setting.

At the time of installation, determine a reference plane, as

shown in the figure below, and taking sufficient care

against beam misalignment or tilt, install the beam-

emitting and receiving fibers so that they are parallel.

Thru-beam type wide beam fiber mounting

<

FT-KV8 / FT-WKV8

>

How to bend sleeve

•

The bending radius must be R10 mm

R0.394 in

or more.

Please bend gradually using the fiber bender (

FB-1

) or a

round bar of

"

20 mm

"

0.787 in

or more.

Note: Do not bend the sleeve of side-view type, narrow beam type, narrow-

view type and ultra-small diameter type fiber.

Method of fixing fiber cable

•

If fixing the fiber cable in position, make sure that it is set in

a manner as shown below, so that no load is applied on the

fiber. (Excluding

FT-H35-M2

,

FT-H35-M2S6

,

FD-H35-M2

and

FD-H35-M2S6

)

For a allowable bending radius of 25 mm (0.984 in)

Use of heat-resistant type fiber

•

Use by keeping 150 mm

5.906 in

, or more, of the heat-

resistant fiber cable part at normal temperature.

Summary of Contents for Digital Fiber Sensor FX-301

Page 64: ...527 FX 301 F ...