9-18

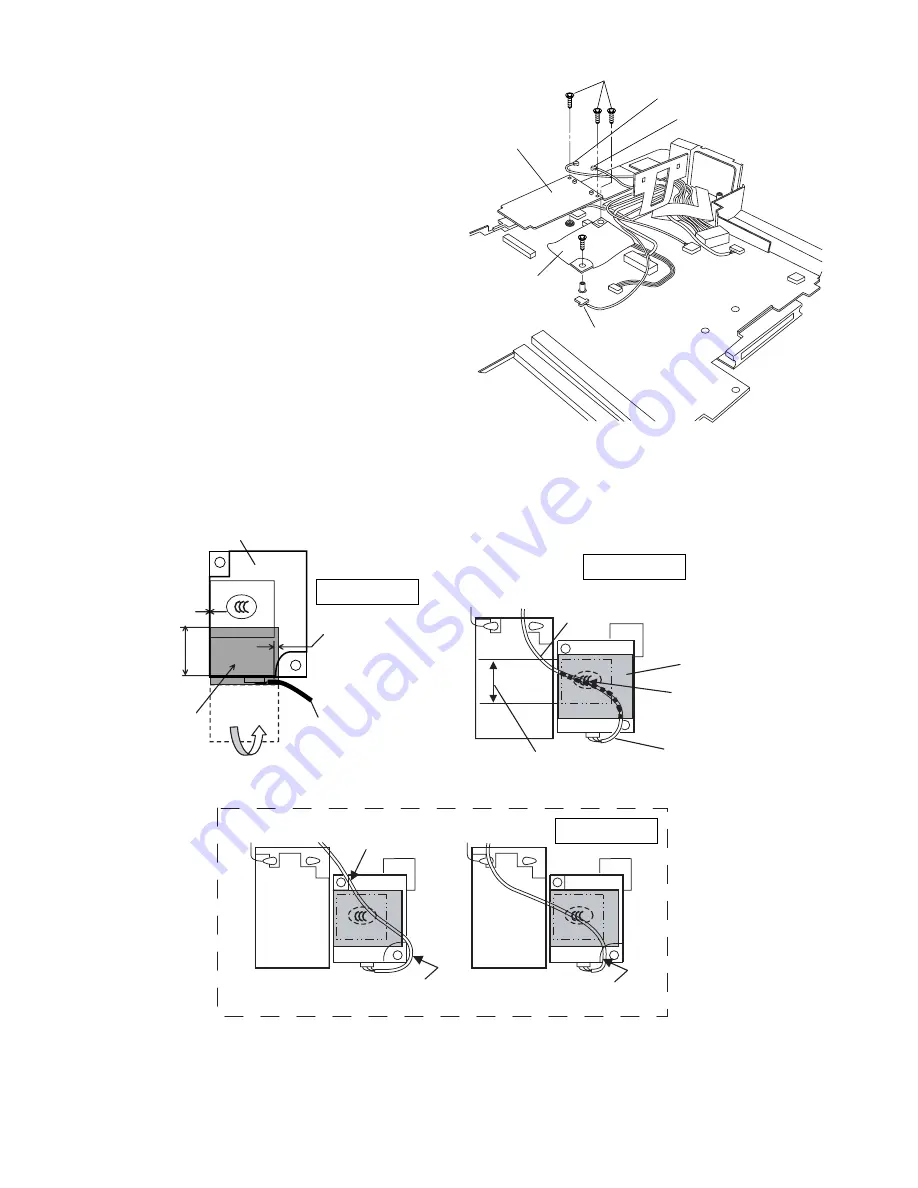

9.2.11. Setting the Wireless Module and MDC Module

1. Connect the Modem Cable to the Connector, and fix the

MDC Module to the Main PCB using the two

Screws<N9>.

2. Connect the Wireless Module to the Connector of the

Main PCB, and fix it using the two Screws<N9>.

3. Connect the two Antenna Cables to the two Connectors

on the Wireless Module.

• Antenna Cable (Black): MAIN Connector

• Antenna Cable (Gray): AUX Connector

Screws <N9>: DFHE5025XA

Q

Arranging the Modem Cable

Antenna Cable (Black)

Antenna Cable (Gray)

<N9>

<N9>

MDC Module

Wireless Module

Modem Cable

10–3mm

Safety Working

MDC Module

Modem Cable

<Preparation for assembly of the MDC Module>

Ensure the Kapton Tape is

overlapping the Shrink Tube

by 1 mm or more.

Fix the Connector

using the Tape.

Fold back and attach to the back side

of the MDC Module.

Arranging the Modem Cable

<Bad example>

Kapton Tape

Ensure the Cable does not run over the Screw.

Ensure the Cable does not come over the end

of the MDC Module.

Safety Working

Ensure both of the inlet and outlet

of the Cable are within the frame.

Avoid any stress on

the outlet of the Cable.

Pass the Cable over

the CCC mark.

Coming over the end of the Screw.

Coming over the end

of the Screw.

<Good example>

Coming outside of the frame.

Safety Working