AV6 (CS) Switches

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

AECTB60E 202110

Panasonic Corporation 2021

GUIDELINES FOR USAGE

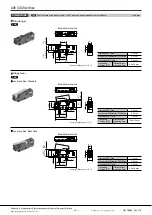

Fastening of the switch body

1) To secure the switch, please use an M2.3 screw on a flat

surface and tighten using a maximum torque of 0.29 N·m.

It is recommended that both flat metal washer and spring

washers be used with the screws and adhesive be applied

to lock the screws to prevent loosening of the screws.

2) Be sure to maintain adequate insulating clearance between

each terminal and ground.

3) When the operation object is in the free position, force

should not be applied directly to the actuator or pin plunger.

Also force should be applied to the pin plunger from vertical

direction to the switch.

4) In setting the movement after operation, the over-travel

should be set more than 70% as a standard.

With the lever type, do not apply excessive force in the

direction opposite to the movement, or from the horizontal

direction.

5) After installing, attach with the lever side oriented downward

to avoid the weight of the lever.

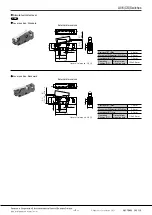

About the connector

1) The connector on the AV6 (CS) switch is designed to fit with

the XA connector produced by JST Mfg. Co., Ltd. Do not

use any connector other than the specified connector, or

solder the terminals directly.

2) Make sure leads are arranged so that no constant force is

applied to them when the connectors are mated.

3) Keep the connector straight when inserting it. If it is inserted

at an angle, it may snag near the entrance, or it may be

inserted too forcefully.

4) Problems thought to be caused by the XA connector, which

is specified as conforming to the AV6 (CS) switch connector,

are not covered by the warranty. Please contact JST Mfg.,

Co., Ltd. and request cooperation in resolving the problem.

Selection of switch

Please make your selection so that there will be no problems

even if the operating characteristics vary up to ±20% from the

standard values.

Environment

Avoid using and storing these switches in a location where

they will be exposed to corrosive gases, silicon, or high dust

levels, all of which can have an adverse effect on the contacts.

Precautions concerning circuits

The AV6 (CS) switch is designed specifically for low-voltage,

low-current loads. Avoid using it at loads that exceed the rating

load.

Quality check under actual loading conditions

To assure reliability, check the switch under actual loading

conditions. Avoid any situation that may adversely affect

switching performance.

Please refer to

"the latest product specifications"

when designing your product.

•Requests to customers:

https://industrial.panasonic.com/ac/e/salespolicies/

ー 7 ー