5

PZ Series 150-250-500-1000 Shaker Cleaner

Portable collectors may require special installation

accommodations.

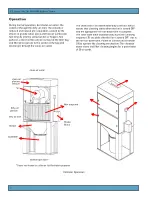

Hoisting Information

Failure to lift the collector

correctly can result in severe

personal injury and/or property damage.

Use appropriate lifting equipment and adopt

all safety precautions needed for moving and

handling the equipment.

A crane or forklift and qualified operator are

recommended for unloading, assembly, and

installation of the collector.

Location must be clear of all obstructions, such

as utility lines or roof overhang.

Use spreader bars to prevent damage to collector’s

casing.

Check the Specification Control drawing for weight and

dimensions of the collector and components to ensure

adequate crane capacity.

Allow only qualified crane or forklift operators to lift the

equipment.

Refer to applicable OSHA regulations and local codes

when using cranes, forklifts, and other lifting equipment.

Lift collector and accessories separately and assemble

after collector is in place.

Use drift pins to align holes in section flanges during

assembly.

Use all lifting points provided.

Use clevis connectors, not hooks, on lifting slings.

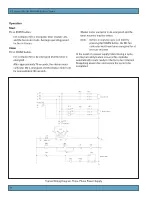

Collector Location

Pakzy equipment is not

designed to support site installed

ducts, interconnecting piping, or electrical

services. All ducts, piping, or electrical

services must be adequately supported to

prevent severe personal injury and/or property

damage.

When hazardous conditions or materials are

present, consult with local authorities for the

proper location of the collector.

Dust collection equipment may reach peak

sound pressure levels above 80 dB (A). Noise

levels should be considered when selecting

collector location.

Locate the collector to ensure easy access to electrical

supply, to simplify solids collection container handling

and routine maintenance, and to ensure the straightest

inlet and outlet ducts.

Provide clearance from heat sources and avoid any

interference with utilities when selecting the location.

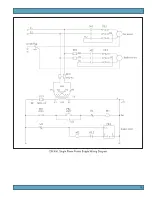

Standard Equipment

The collector has a high center-

of-gravity and may overturn if not

secured properly.

Secure the collector to the lifting device.

Use care when moving the collector.

Unimaster dust collectors are delivered partially

assembled. Collector installation, optional equipment

assembly, and electrical connections are completed at

the job site.

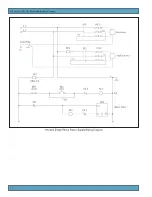

Anchors must comply with local

code requirements and must be

capable of supporting dead, live, wind, seismic,

and other applicable loads.

Anchor sizes shown are provisional, as final

anchor sizing will depend on jobsite load

conditions, collector location, foundation/

framing design variables and local codes.

Consult a qualified engineer for final selection

of anchors.

Hopper and Leg Installation

Reference Typical Foundation Anchor and leg assembly

drawing shipped with the collector prior to starting

assembly.