13

PZ Series 150-250-500-1000 Shaker Cleaner

Filter Removal

1. Turn power to collector OFF. Open or remove the

filter access door.

Lower the retention handles in the bag chamber

(for UMA 40 model size, loosen wing nuts on top of

clean air plenum until filter frame releases from seal

gasket).

3. Slowly remove the filter frame assembly from the

collector.

Note: This may require two people.

4. Remove filter inserts and filter bags. Check for

broken or worn inserts especially at any areas of

filter bag damage and dispose of properly. Replace

any missing or damaged filter inserts.

5. Remove any dust or debris from the dirty-side

tubesheet gasket.

Filter Installation

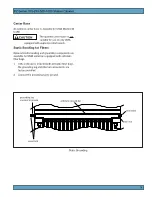

1. Insert the filter bag into the filter frame placing

individual filter pockets between the locating bars

and fold filter bag collar over the top flange.

2. Place insert edging around sides and bottom edges

of each filter insert.

3. Insert one filter insert into each filter bag pocket.

Instruct all personnel on safe use and maintenance

procedures.

Use proper equipment and adopt

all safety precautions needed for

servicing equipment.

Use appropriate access equipment and

procedures. Note the standard collector is not

equipped with access platforms unless noted

on the specification drawings.

Electrical service or maintenance work must

be performed by a qualified electrician and

comply with all applicable national and local

codes.

Turn power off and lock out all power before

performing service or maintenance work.

Do not install in classified hazardous

atmospheres without an enclosure rated for

the application.

Maintenance Information

Filter Removal and Installation

Use proper safety and protective

equipment when removing

contaminants and filters.

Dirty filters may be heavier than they appear.

Use care when removing filters to avoid

personal injury and/or property damage.

Turn power off and lock out all power before

performing service or maintenance work.

Do not operate with missing or damaged filters.

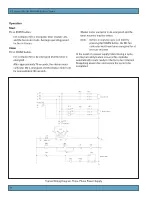

Operational Checklist

1. Monitor the physical condition of the collector and

repair or replace any damaged components.

Routine inspections will minimize downtime and

maintain optimum system performance. This

is particularly important on continuous-duty

applications.

2. Monitor pressure drop across filters.

Abnormal changes in pressure drop may indicate a

change in operating conditions and possibly a fault

to be corrected.

3. Monitor exhaust.

4. Monitor dust disposal.