8

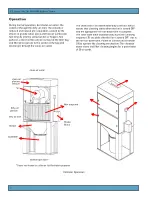

The UMA controller operates the fan and shaker in the

proper sequence to ensure effective filter cleaning. The

controller contains an across-the-line fan starter and an

across-the-line shaker motor starter.

1. Mount the controller in a convenient accessible

location, free of vibration and temperature extremes.

Do not mount the controller

directly to the collector.

Mechanical vibration can damage the control.

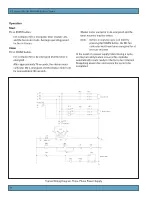

2. Using the wiring diagram supplied with the controller,

connect the power lead from a customer-supplied

disconnect switch to the terminal block inside the

controller, complying with all applicable codes for

motor branch circuits.

3. Install conduit from the controller to the junction box

located on the side of the collector. Use conduit and

fittings compatible with the rating of the controller’s

enclosure.

4. Make the connections from the manual motor

protector inside the controller to the terminal block in

the junction box.

UMA Controller

The UMA Controllers are designed to work with three-

phase, 50- or 60-Hz power supplies or optional single-

phase power.

Inlet Assembly

All models are shipped with the inlet specified at the

time of order. Side inlets are not interchangeable with

back inlets. Contact Pakzy if additional changes are

necessary.

1. Remove the inlet blank from the specified location.

2. Replace damaged sealant if necessary.

3. Secure inlet to collector using the hardware

removed in Step 1.

All electrical wiring and connections, including electrical

grounding, should be made in accordance with the

National Electric Code (NFPA No. 70-latest edition).

Check local ordinances for additional requirements that

apply.

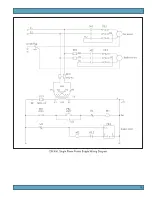

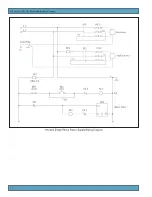

The appropriate wiring schematic and electrical rating

must be used. See collector’s rating plate for required

voltage.

An electric disconnect switch having adequate amp

capacity shall be installed in accordance with Part IX,

Article 430 of the National Electrical Code (NFPA No.

70-latest edition). Check collector’s rating plate for

voltage and amperage ratings.

Refer to the wiring diagram for the number of wires

required for main power wiring and remote wiring.

Mount controller outside the influence area of any

explosion relief panels, if present.

Electrical installation, service,

or maintenance work must

be performed by a qualified electrician and

comply with all applicable national and local

codes.

Turn power off and lock out all power before

performing service or maintenance work.

Do not install in classified hazardous

atmospheres without an enclosure rated for

the application.

Electrical Wiring

PZ Series 150-250-500-1000 Shaker Cleaner